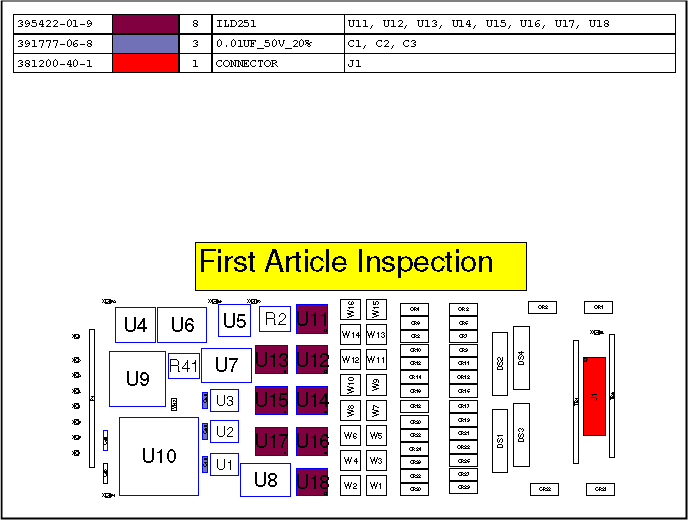

FIRST ARTICLE INSPECTION

First

Article

Inspection

in electronic manufacturing assembly normally is the process by which the first

or one of the first few PC boards being assembled is inspected and verified.

This inspection is done typically early in a batch run when many PC boards are

being assembled to validate the process and assure that the assembly is correct

before continuing. Depending on the QC Inspection Terminology used First

Article

Inspection

may be less commonly referred to as First Piece Inspection.

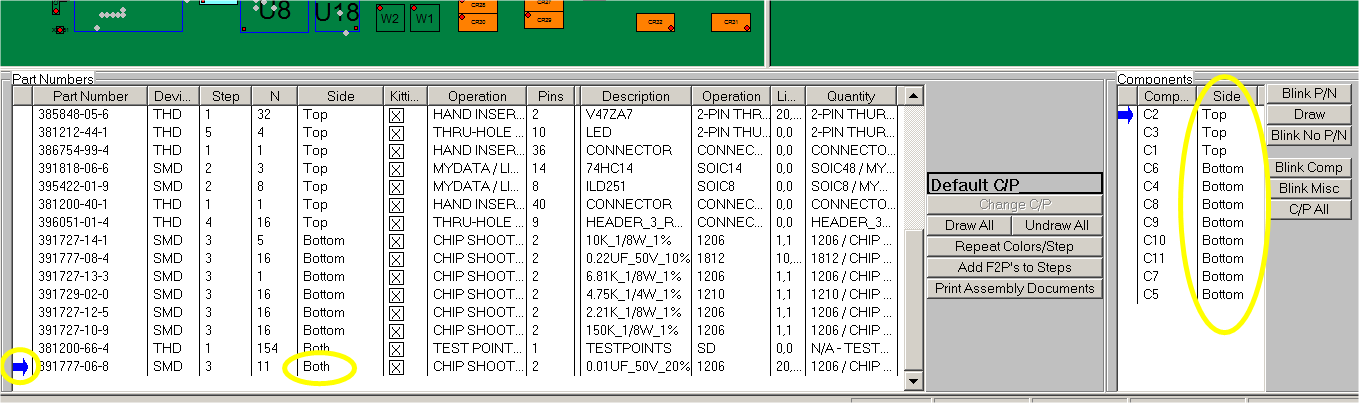

Using the Unisoft software First

Article

Inspection

can be done on either the top or the bottom or both surfaces of the PCB. The

Smart Color inspection feature

of the Unisoft software

has been enhanced and allows quick inspection by

blinking by part numbers and checking off the inspected components on the top,

bottom or both surfaces.

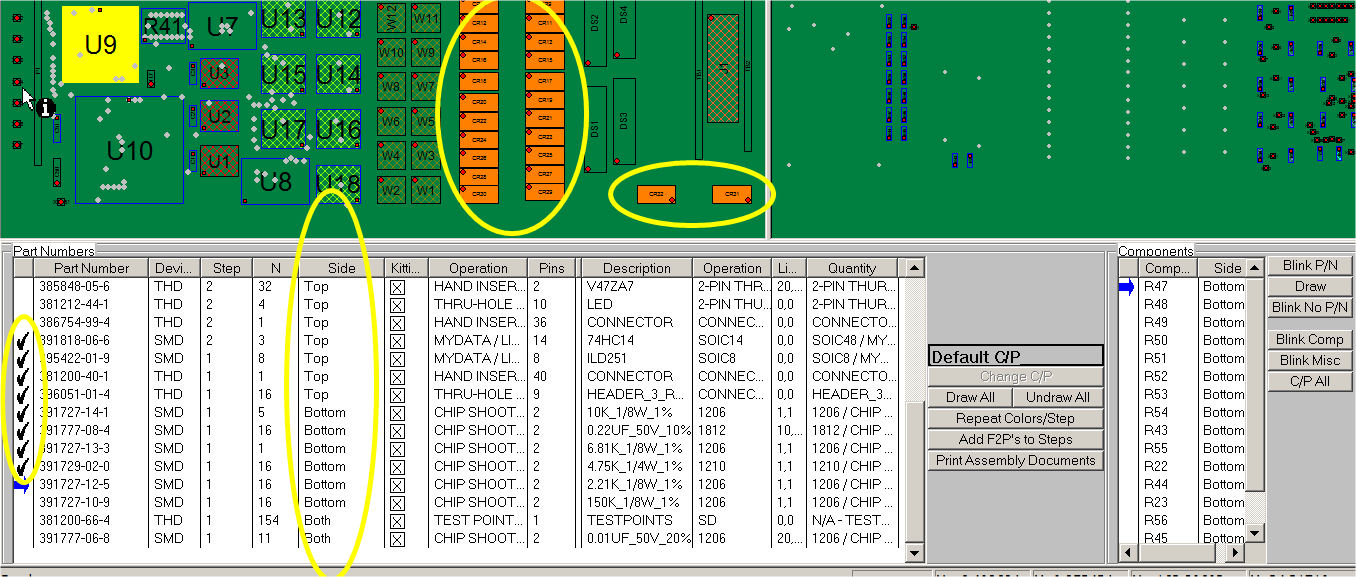

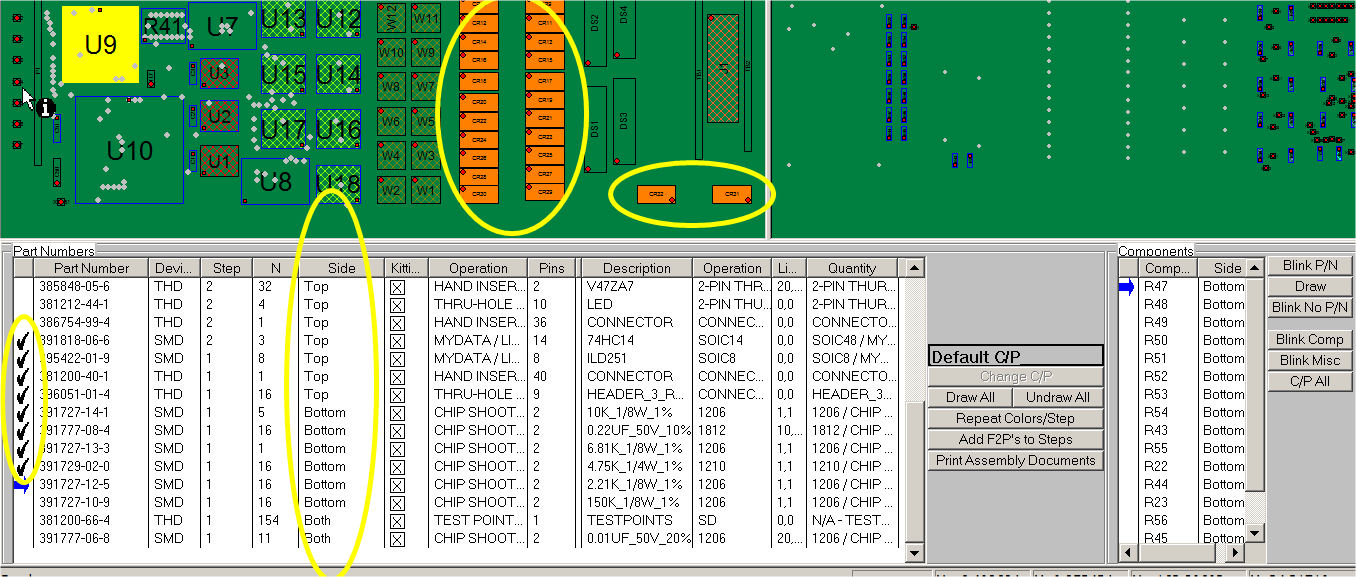

If the part number

components

they wish to inspect is on both surfaces

of the PCB assembly ( PCBA ) then select that

part number and on the right-hand side of the Smart Color window sort by SIDE

and inspect the components

on their respective surfaces.

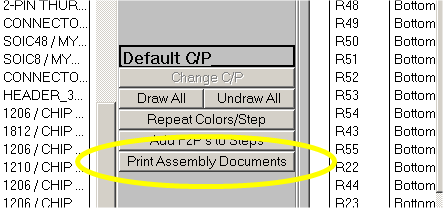

At this point the inspection is complete and if you choose to you can print an

inspection document by using the Print Assembly Documents feature.