Skip navigation

For over 35 years, Intelligent PCB Manufacturing

Automation Software

Be production ready in minutes, not days.

Below we will briefly review adding operation Steps to the Unisoft

software and then introduce adding Substeps to those Steps. We assume

that you have a basic working knowledge of the Unisoft software. If

you have questions please contact us.

The Unisoft software can

add

Steps

to part numbers on the PCB you are working on to partition them into

different assembly operations, inspection operations, etc.

These component part

numbers in their Steps can then be assigned unique colors, instructions and

more. Then process documents, kitting labels., etc. can be created.

When the PC Board and BOM are first imported into the Unisoft

software all Step numbers are defaulted to Step 1.

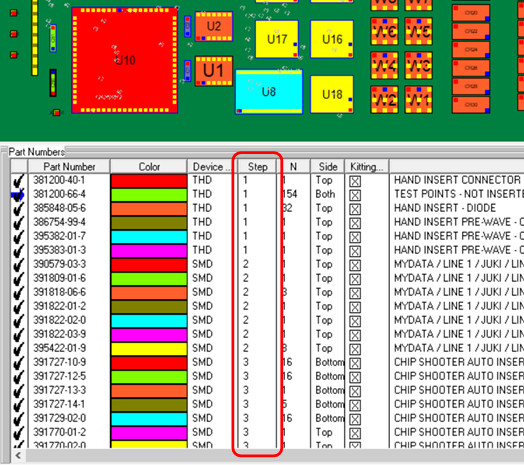

In the

figure above at the bottom of the software display is the Smart Color window and to the right of

the PART NUMBER field you will find the STEP field. In this field you may

optionally add STEP NUMBERS to part numbers in order to create separate

unique steps in the PC Boards assembly process (for example: Step 1 for Hand

Inserts, Step 2 for Mydata/Mycronic assembly machine placements, Step 3 Chip

Shooter component placement, etc.).

To assign a STEP NUMBER to a part number

at the bottom of the display double click on a part number and edit the STEP

field with a step number.

SUBSTEPS: These

Steps can further be broken down into Substeps. We will review the Substep process

below.

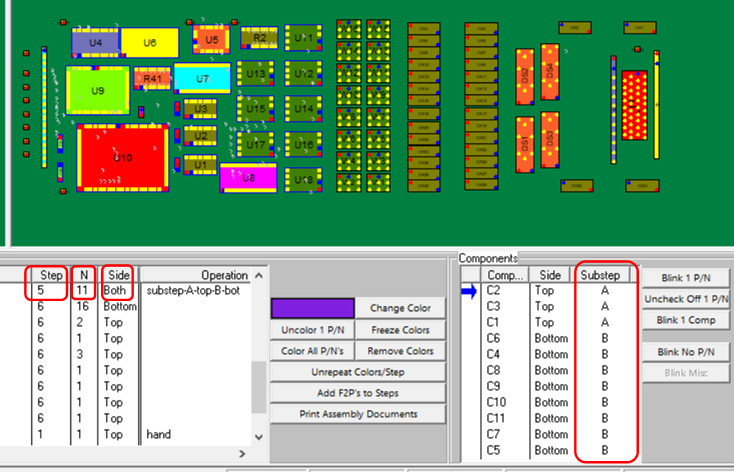

In the above figure we have an example of a Substep

that was added. In this case the Step number is 5 and there are 11

components for this part number in this step and those 11 components are

located on both sides of the PCB. In the right hand side of the figure

we created Substeps A and B for this Step #5. Now Substep 5A

includes the 3 components on the top side of the PCB and Substep 5B includes

the 8 components on the bottom side. As a result the assembly

documents, inspection documents. etc. created will be separated into two

separate Substeps and used accordingly as required as part of the

manufacturing of the finished assembly process.

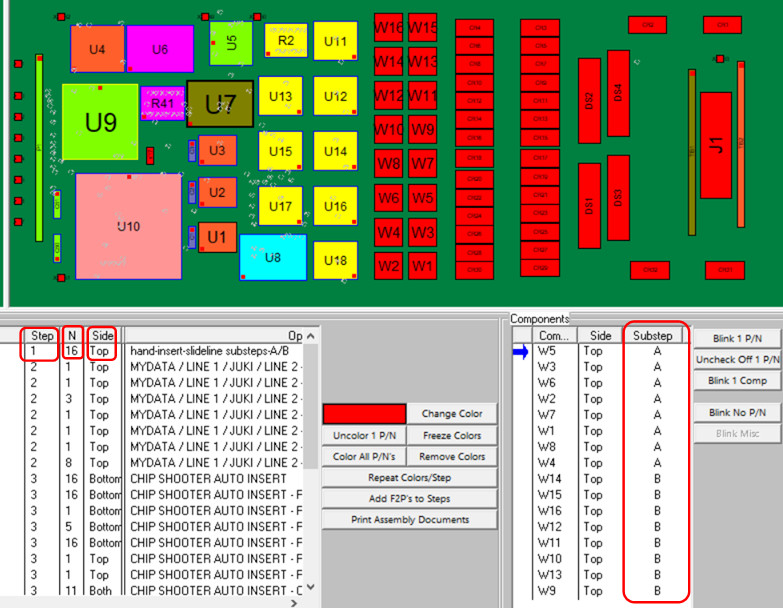

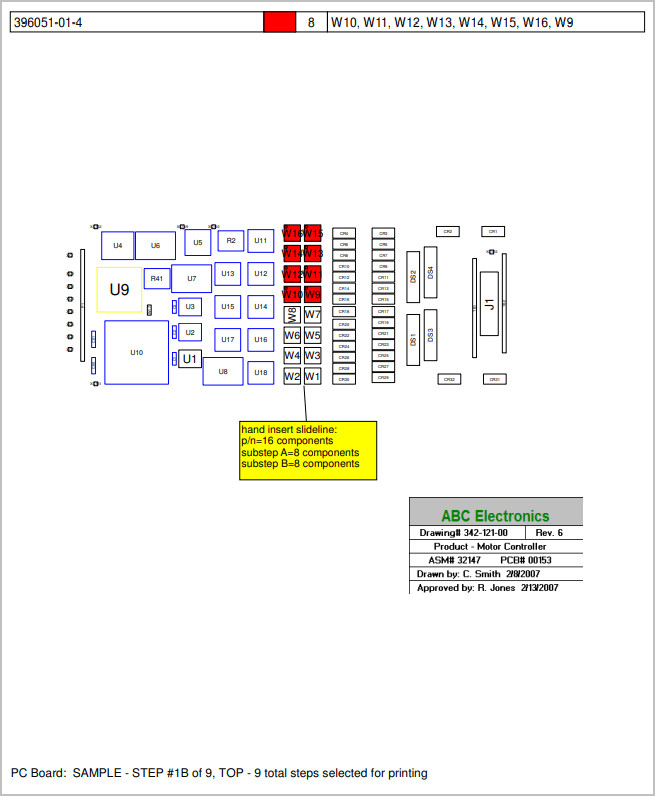

In the figure above is another example of a use for

Substep. For instance, if the PCB was being assembled in a slide line and

one of the part numbers being assembled had a large quantity of components

and you wanted to distribute that among the slide line assemblers then you

could use Substep to assign a certain number of components to each

assembler.

In the above figure in this case the Step number is

1 and there are 16 components for this part number in this step and those 16

components are all located on the top side of the PCB. In the right

hand side of the figure we created Substeps A and B for this Step #1.

Now Substep 5A includes 8 components of the 16 components and Substep 5B

includes the balance of the remaining 8 components. As a result the

assembly documents, inspection documents. etc. created will be separated

into two separate Substeps and used accordingly as required as part of the

manufacturing of the finished assembly process.

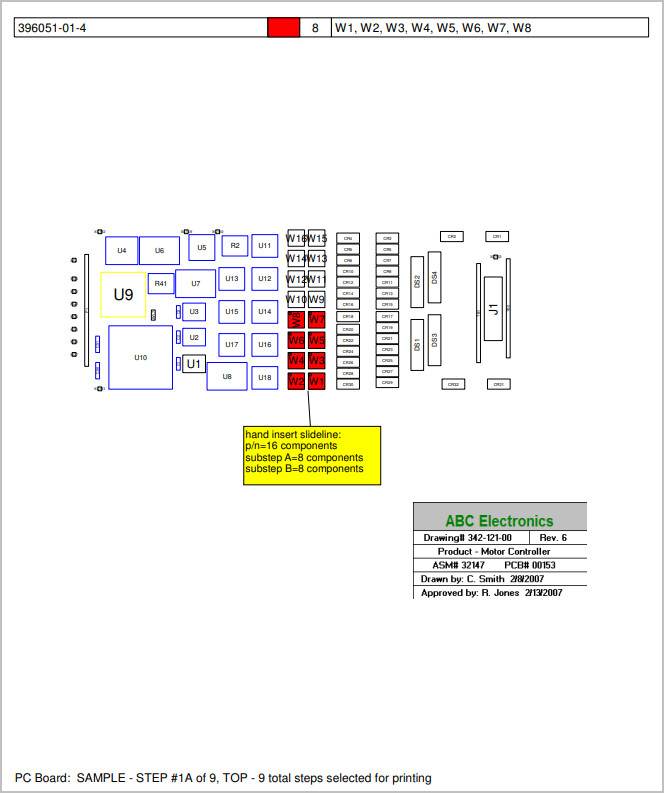

The 2 figures below

are the resultant assembly documents created for Substeps 5A and 5B.

The first figure below, Substep 5A, includes 8 components of the 16 components and

the second figure, Substep 5B, includes the balance of the remaining 8

components.

I

If a

Step has multiple part numbers and a Substep is assigned with the same

letter A through E for different part numbers within the Step then those

components using that same Substep will be join together within that

Substep.

Related information:

Assembly documents -

sample of how to create assembly documents

Assembly documents - adding steps to part numbers

Assembly documents -

manual "tutorial 1 - creating assembly/process sheets, annotation overlays and kitting labels"

Assembly

documents - printing assembly documents

Assembly documents -

kitting labels-1

kitting labels-2

kitting labels-3

Assembly documents - single page per step.

Assembly documents - multiple pages per step

Assembly documents -

powerpoint and custom types

Assembly

documents - editing multiple assembly steps

Assembly documents - add pcb photos, etc. to the display background

Assembly documents -

for paperless assembly instructions when using the display only for slide

line pcb assembly, etc.

Barcodes on the display and assembly

documents