Skip navigation

For over 40 years, Intelligent PCB Manufacturing

Automation Software

Be production ready in minutes, not days.

The process outlined below with the Cells Route Builder and the Cells Work Order

Admin software will step you through creating your own process routings for use in the

CELLS Workflow MES software.

The CELLS Workflow MES is designed to be used in any industry to track

product. In addition Unisoft has

a specialty in providing automation software for the

electronic manufacturing industry.

If you have not installed the

CELLS Workflow MES software click here.

For

help contact Unisoft and we can go online with you.

Important:

If you do not wish to create your own route for your product

as outlined in the procedure below at

this time then please go to the following link

CELLS Tutorial manual by clicking here. There you

will get a detailed understanding of the CELLS software

and you will be

walked through a sample database provided that contains 200 serialized units in

one work order and 10 subassemblies in another work order & the units are in the

process of being assembled. By following the instructions there you will get a

good idea of how CELLS Workflow MES works by moving product forward in that

supplied sample process routing.

About

the Cells Route Builder:

To create your own process routing for your products the CELLS Route

Builder, that will be outlined below, provides a quick natural

way to populate the

PROCESS, NEXT_STEP, OPERATIONS and

CONDITIONS tables by using an Excel spreadsheet.

These tables direct the CELLS Workflow MES software on how to route your

products. With

CELLS Route Builder you can enter data according to the flow

of the process being described rather than entering data directly into these

tables in the database in a fragmented, out-of-order manner.

The CELLS Route Builder uses a

simple Excel spreadsheet interface and creates new

production process

routings

in

minutes. You can create new process

routings from

scratch or

import an existing

process

routing from CELLS Workflow then

modify it and export it out as your new

process routing.

The CELLS Route Builder is a

Microsoft Excel

file

“CELLS-Route-Builder.xlsm”.

The CELLS Route Builder can be started in any of the following ways:

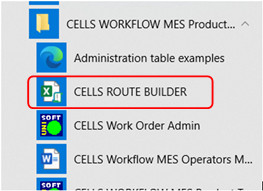

- A CELLS Route Builder icon is

located on the desktop.

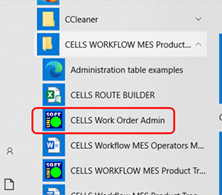

- In the Start/Programs Menu in the

"CELLS WORKFLOW MES Product Tracking" folder click CELLS ROUTE BUILDER.

- File location by default c:\program

files(x86)\cells\CELLS-Route-Builder.xlsm

CELLS Route Builder Tables:

To use the CELLS Route Builder, you first must have some understanding of four tables in the CELLS database:

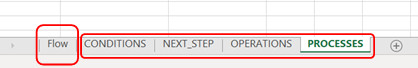

In the CELLS Route Builder these four tables are locate in the tabs at the

bottom. There is also a fifth table, the FLOW table, and it is where the user

brings the other

tables together in a simplified organized manner to create a process flow to build their product

routing.

General information about entering and editing data in the CELLS Route Builder:

1. For the most part, you can treat the spreadsheet in the CELLS Route Builder as you would any spreadsheet. Specifically, you can repeatedly do the following:

a. Change an operation or a condition in a cell. There are three ways:

i. Click the cell, click the dropdown arrow for the cell, and select an operation/condition.

ii. Double-click the cell and type an existing operation/condition.

iii.Double-click the cell and type a new operation/condition. The CELLS Route Builder will prompt you for information that describes the new operation/condition.

b. Delete operations or conditions in one or more cells by selecting a range of cells and clicking the delete key.

c. Delete one or more entire rows.

d. Insert rows.

e. Cut and paste ranges and rows.

2. You have the option of changing data in the other sheets in the workbook, namely CONDITIONS, NEXT_STEP, OPERATIONS, and PROCESSES. Any changes you make to these sheets will be reflected in the FLOW sheet.

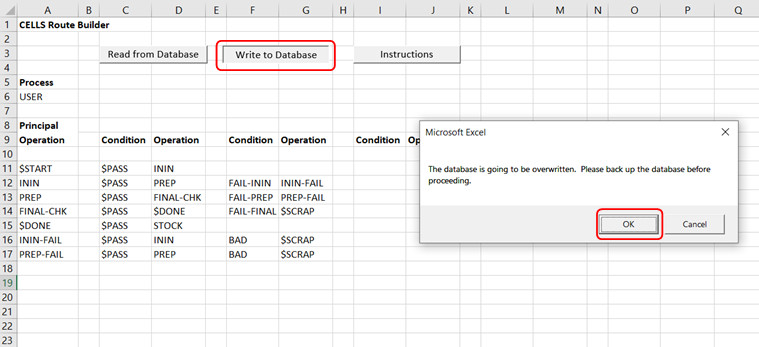

3. When you are satisfied with the state of the description of the steps in the process, click the WRITE TO DATABASE button to save the data. Changes to data in any of the sheets will be written to the database.

About the Cells Work Order Admin:

After the CELLS Route Builder creates the route then the Cells Work Order Admin

adds the Assemblies as needed and creates the Workorder that the process route is

associated with.

Optional method:

The

Cells Route Builder and the Cells Work Order Admin automate the process of

populating the CELLS Workflow MES software database tables.

It is

recommended to use the Cells Route Builder and the Cells Work Order Admin. However

if desired these database tables can also be populated manually

directly in the database. Some individuals prefer the manual method or a

combination on some projects. If you wish to manually enter data into the

tables here are examples of how they look and these two manuals are

helpful System

Administrator Guide

and

Database tables Guide.

Note:

Usually it is good practice to backup any CELLS database before it is used

with

the CELLS Route Builder. The sample

database that comes with the software is CELL32.MDB and the file is

located at

C:\Users\xxx\Documents\unisoft-cells-databases\cells32.mdb where

xxx is

the Windows user login name when the software was installed. You can have your

own databases located anywhere you wish.

GETTING STARTED:

Note:

Before the CELLS Route Builder can be used the CELLS software needs to be

connect it to a database so if you have not already done this please do so now

by going to the

CONFIGURATION section

https://www.unisoft-cim.com/cells_download.htm#config . After you have

completed the configuration please return here and continue below.

There are four steps below:

1) Creating your own process routings using CELLS Route Builder.

2) The process routing created is assigned a new Assembly and Work Order using the CELLS Work Order Admin.

3) Test

the new process by running the route through the CELLS Workflow MES software.

4) Database Tables that are edited directly.

Note:

Throughout the procedures outlined below

you can substitute in your own data for a

product you are building.

1) Creating your own

process routings using CELLS Route Builder:

What follows is the short version for this step "1) Creating your own process routings using CELLS Route Builder:" and below this short version is the detailed version with a step-by-step breakout and graphics of what is happening.

Short version:

First start the CELLS Route Builder.

Click READ FROM DATABASE.

Click USER from the pulldown list and click READ FROM

DATABASE.

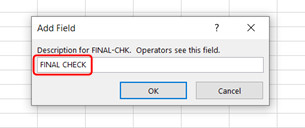

Creating a new Operation:

Below the Operation PREP insert a row as you would normally

in Excel.

Select the cell A14 and type at the top or directly in the

cell FINAL-CHK<enter>

Next click YES.

Type FINAL CHECK and click ok.

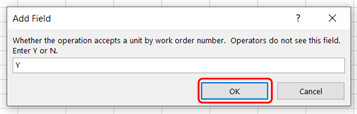

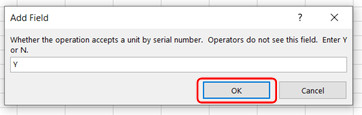

Click OK. Click OK.

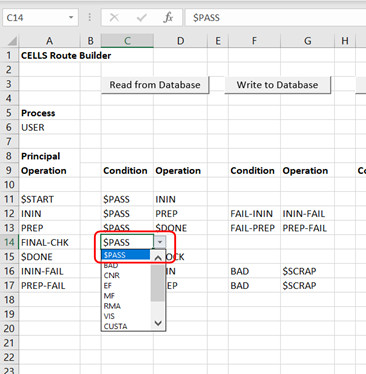

Click cell C14 then from the pulldown list click Condition

$PASS.

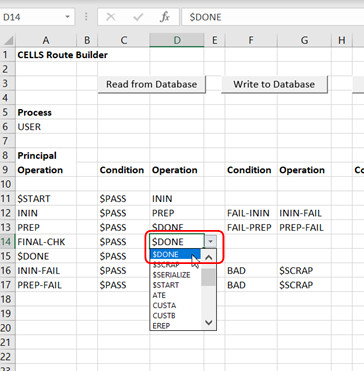

Click cell D14 then from the pulldown list click Operation

$DONE.

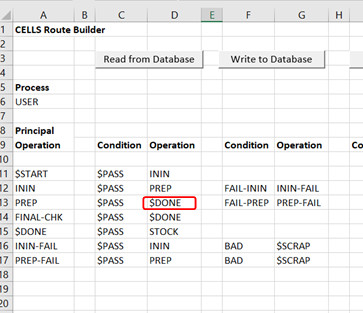

Click cell D13 then from the pulldown list click Operation

FINAL-CHK.

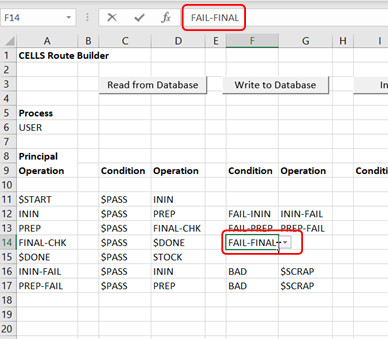

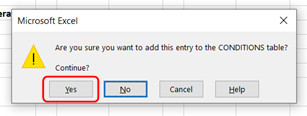

Creating a new Condition:

Select the cell F14 and type at the top or directly in the

cell FAIL-FINAL<enter>

Next click YES.

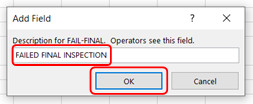

Type FAILED FINAL INSPECTION and click OK.

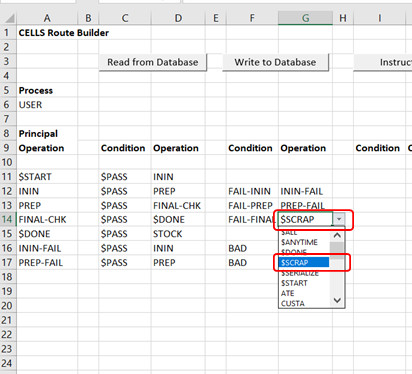

Click cell G14 then from the pulldown list click Operation

$SCRAP .

To save the process:

Click WRITE TO DATABASE and click OK.

-------------

Detailed version:

First start the

CELLS Route Builder.

In the Start/Programs Menu in the "CELLS WORKFLOW MES Product Tracking" folder

click CELLS ROUTE BUILDER.

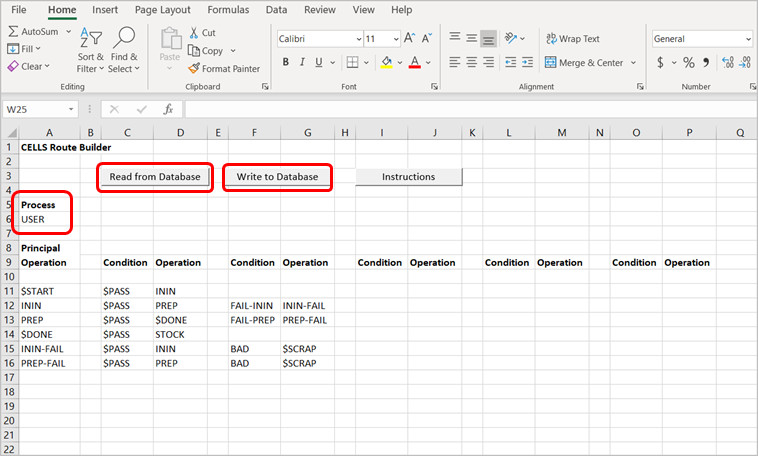

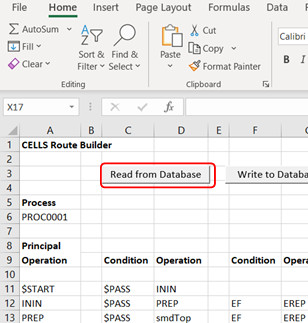

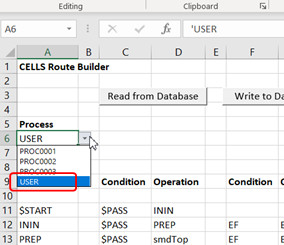

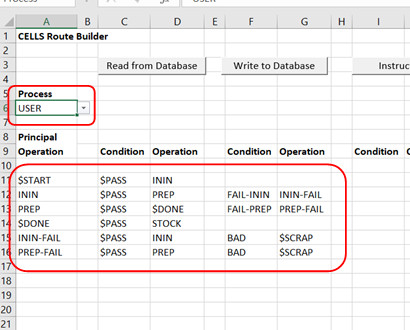

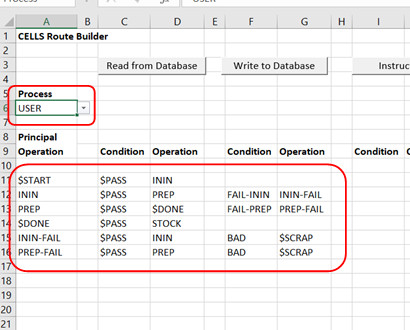

By default you will be on the FLOW tab of the CELLS Route Builder. Click READ FROM

DATABASE.

Click the Process USER from the pulldown list and click READ FROM DATABASE.

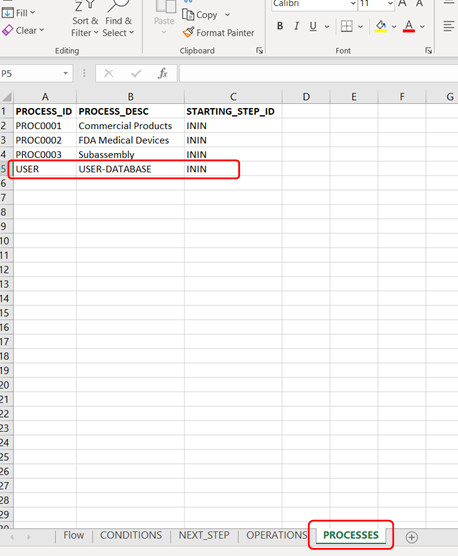

The Process USER was previously created but is not complete and we will complete

that route in the procedure below. You can see that process and others

by clicking the PROCESSES tab in the CELLS Route Builder.

For your product

routings you can call the Process whatever name you desire for any industry you

are in. For example: PCB-321-ASSY, PCB-TEST, SERIALIZE-BOARD, ASSEMBLY/TEST,

BLADE-ASSY-INSTALL, CERAMIC, COMMERCIAL-PRODUCTS, ENGINE-MAINTENANCE,

FDA-MEDICAL-DEVICES, GENERAL-MAINTENANCE, OVERHAUL, PASTRY-FROSTING, PATH-1,

SUBASSEMBLY, VALVE-REPAIR, VEHICLE-1, XYZ-SERIES-BENDING, etc.

The result is in the figure below.

Our Process we are calling USER and we have a few Operation steps already in

this process to get us a head start.

Note for your product routings you can

call the Processes and Operations whatever names you desire and you can also

start with zero Operation steps to start with

if you wish.

To save time most customers when creating a new Process will READ FROM DATABASE

a Process that they have already created. Next they simply edit that Process

accordingly for the new process and then they WRITE TO DATABASE and that

new Process is now part of the

database.

Creating a new Operation:

Next we will insert a row and create an new Operation.

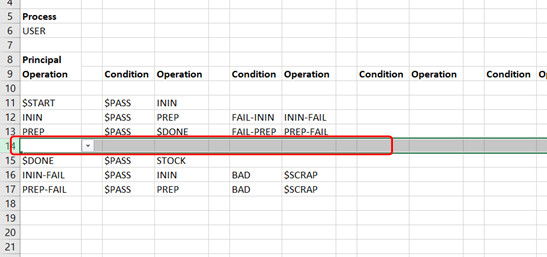

Below the Operation PREP insert a row as you would normally in Excel.

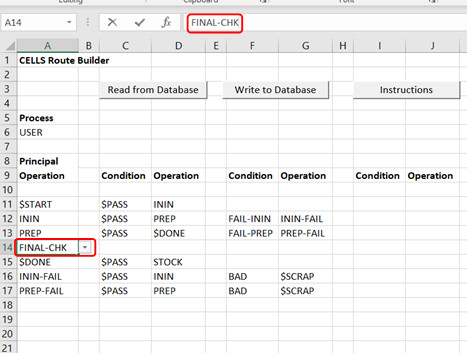

Select the cell A14 and type at the top or directly in the cell FINAL-CHK<enter> for the new Operation and this is the short mnemonic

for the Operation name.

For your product

routings you can call the Operation whatever name you desire for any industry

you are in. For example: SMD-TOP, ATE, PCB-INSPEC, BARCODE, BOTTLE-FILL/LABEL,

COATING, DIE-CUT, FIBERGLASS, GLUE, KITTING, MILLING, PACK, PICK-PARTS, PREP,

PRESS, SEWING, SHIP, X-RAY, etc.

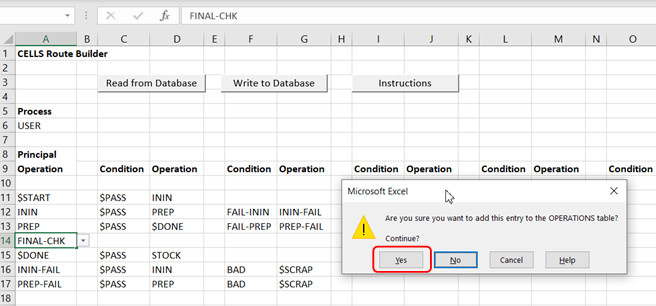

Next click YES.

This window is the long name for the Operation. Type FINAL CHECK and click OK. Note for your product you can use whatever name you desire.

This window asks whether the Operation will accept the unit by work order and the default is Y. Click OK.

This window asks whether the Operation will accept the unit by serial number and the default is Y. Click OK.

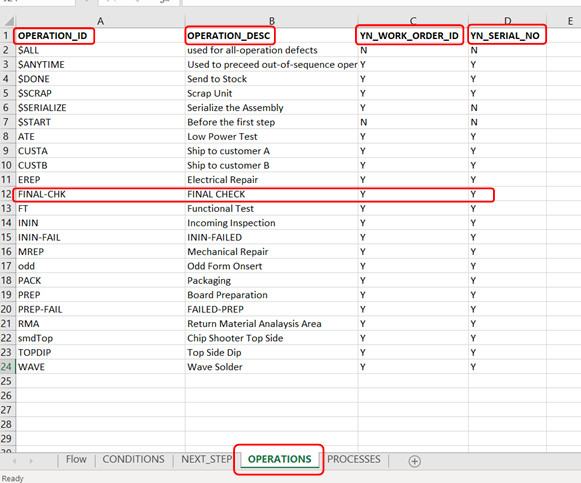

The result is this new Operation FINAL-CHK is created and you can

see that Operation by clicking the OPERATIONS tab in the CELLS Route Builder.

Note that there are many Operations located in this OPERATIONS tab and this is

because all the Operations previously created that are in the database CELLS

Workflow MES is currently connected to are also being listed. This is beneficial

because you can utilize on your new Process an Operation that was used on a

previous product routing.

Click on the FLOW tab at the bottom. Click cell

C14 then from the pulldown list click Condition $PASS.

Note that when a Condition starts with $ such as $PASS it is a reserved

Condition defined internally by the CELLS Workflow MES software and is handled

in a strict specific manner.

Click cell D14 then from the pulldown list click Operation $DONE. Note that this is the same as with Conditions in that when an Operation starts with $ for example $DONE and $SCRAP it is a reserved Operation defined internally by the CELLS Workflow MES software and is handled in a strict specific manner.

In the above steps we added a Condition of $PASS an

Operation routing to $DONE so that is complete.

Because we added a new operation FINAL-CHK we want the previous Operation step

PREP on a $PASS condition to go to Operation FINAL-CHK.

In the figure below PREP is currently going on $PASS

to Operation $DONE so we will adjust that in our next step.

Click cell D13 then from the pulldown list click Operation FINAL-CHK. Now the FLOW is corrected and on $PASS the Operation PREP goes to the next operation step in the routing FINAL-CHK.

In the procedure above we have created one new

Operation and one new step in the routing. You can repeat this process as

much as desired to add additional Operations and steps in your product route.

For help contact Unisoft and we can go online with you.

Creating a new Condition:

Now we will create a new Condition and see how that's done. Select

the cell F14 and type at the top or directly in the

cell

FAIL-FINAL<enter> for the new Condition and this is the short mnemonic

for the Condition name.

For product

routings you can call the Conditions whatever names you desire for any industry

you are in. For example: AOI-FAIL, ELECT-REPAIR, SMD-TOP-FAIL, COSMETIC-REJECT,

CAN-NOT-REPAIR, CUST-B, CUTTING, QA-FAIL, RMA, SPECIAL-PREP, etc.

Next click YES.

This window is the long name for the Condition. Type

FAILED FINAL INSPECTION and click OK. Note for your product you can use whatever name

you desire.

In the procedure above we have created one new Condition. You can repeat this process as much as desired to add additional Conditions in your product route. For help contact Unisoft and we can go online with you.

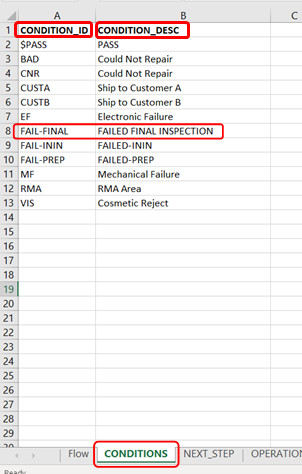

The result is this new Condition FAIL-FINAL is created and you can see that Condition by clicking the CONDITIONS tab in the CELLS Route Builder.

To complete the Condition and Operation set on row 14 we will just sent the unit to an Operation that already exists. Click cell G14 then from the pulldown list click Operation $SCRAP. So if on Operation FINAL-CHK the Condition is FAIL-FINAL the unit will be sent to $SCRAP.

We have finished the process routing above.

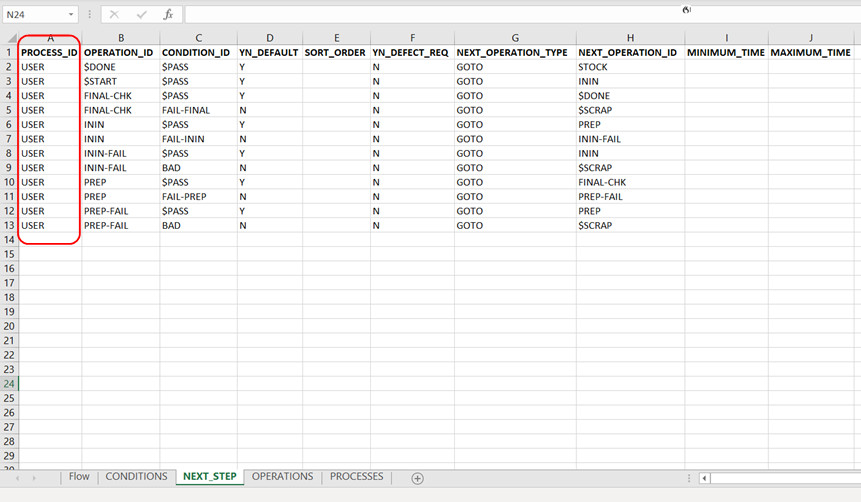

By clicking the NEXT STEP tab in the CELLS Route Builder a different view of the Process USER is displayed with the Operation, Condition, etc. in that Process.

To save the process: Click the FLOW tab and then to save the Process USER click WRITE TO DATABASE and

click OK.

The process USER has now been saved to the database that the CELLS Workflow MES

software is connected too.

2) The process routing created is assigned a new Assembly and Work Order using the CELLS Work Order Admin:

What follows is the short version for this step "2) The process routing created is assigned a new Assembly and Work Order using the CELLS Work Order Admin:" and below this short version is the detailed version with a step-by-step breakout and graphics of what is happening.

Short version:

The process routing created above is assigned a new

Assembly and Work Order using the CELLS Work Order Admin:

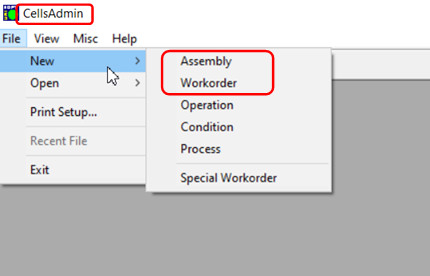

First start the CellsAdmin software.

Creating the ASSEMBLY:

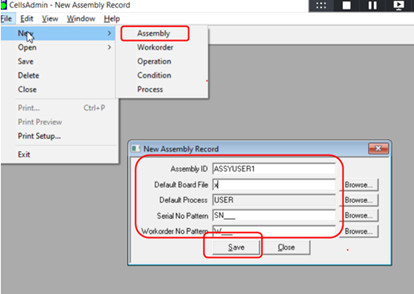

Click FILE / NEW / ASSEMBLY and in the NEW ASSEMBLY RECORD

window type the following in red for each of the fields:

Assembly ID = ASSYUSER1

Default Board File = x

Default Process = USER

Serial No Pattern = SN___ (this is

SN followed by 3 underscores _ )

Workorder No Pattern = W___ (this is

W followed by 3 underscores _ )

Click SAVE when complete. Click CLOSE.

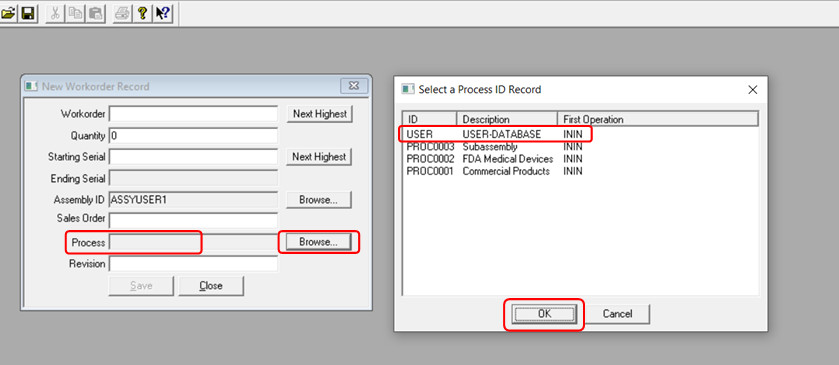

Creating the Work Order:

Click NEW and WORKORDER.

In the ASSEMBLY ID field click BROWSE and select the Assembly

record ASSYUSER1 and click OK.

In the PROCESS field click BROWSE and select the Process ID

record USER and click OK.

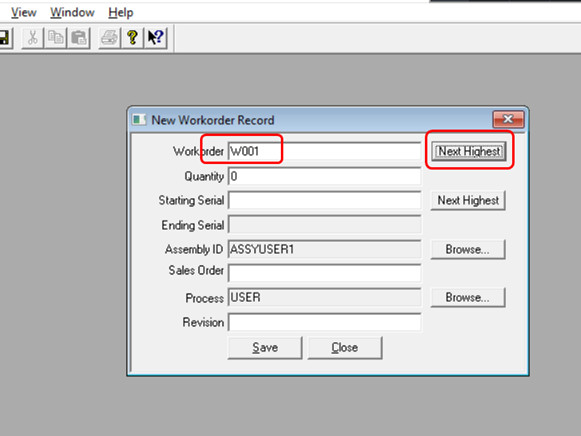

In the WORKORDER field click NEXT HIGHEST and the result is

workorder number W001.

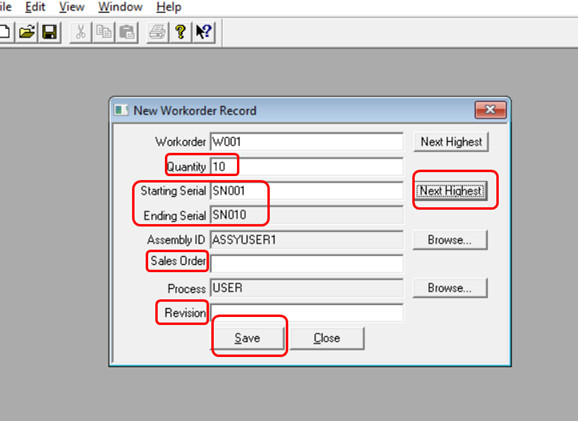

In the QUANTITY field type 10. In the STARTING SERIAL field

click NEXT HIGHEST.

Click SAVE. The Workorder is complete.

-------------

Detailed version:

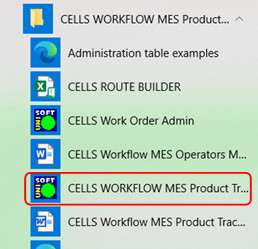

First start the CellsAdmin software. In the Start/Programs Menu in the "CELLS WORKFLOW MES Product Tracking" folder click CELLS Work Order Admin.

Creating the ASSEMBLY:

If no Assembly exists then one needs

to be created and we will do that in the steps that follow. If an Assembly

exists the OPEN / ASSEMBLY menu would be used.

Click FILE / NEW / ASSEMBLY and in the NEW ASSEMBLY RECORD window type the

following in red for each of the fields:

Assembly ID = ASSYUSER1

Default Board File = x

Default Process = USER

Serial No Pattern = SN___ (this is SN

followed by 3 underscores _ )

Workorder No Pattern = W___ (this is W

followed by 3 underscores _ )

Click SAVE when complete. Click CLOSE.

For your product

routings you can call the Assembly (ASSEMBLY ID) whatever name you desire for

any industry you are in. For example: PCB-ASSY-001, PCB-MOD-01,

BUILD-CONTACT-SUBASSEMBLY, BLADE-01, BREAD, CAKES, CERAMIC, DEPOT-ITEM,

DISNEY-CUSTOM-COVER, ENG-MAINT, FLOW-01, OVERHAUL-ITEM, PASTRY, REPAIR-ITEM,

SEGMENT, SEMICONDUCTOR-WAFER, SWEATSHIRT, VALVE-REPAIR, VEHICLE-1, etc.

For your product

routings you can have whatever SERIAL NO PATTERN and WORKORDER NO PATTERN

numbering you desire for your industry.

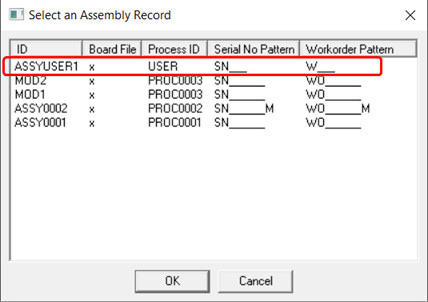

If you wish to verify the result click FILE / OPEN / ASSEMBLY and the

ASSYUSER1 record is listed there.

Creating the Work Order:

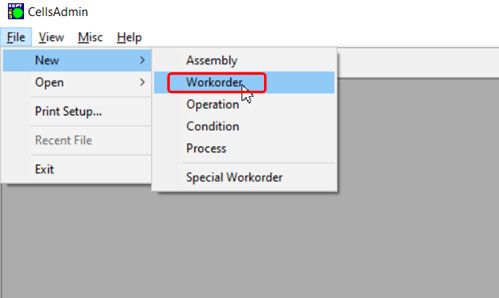

Using CellsAdmin to create the Workorder in the database. Click NEW and WORKORDER.

Note some customers, typically those that are

larger, will use another system such as an ERP to create their Work Order in

place of Unisoft's CellsAdmin. For example the ERP system will write a workorder

entry directly into the CELLS Workflow MES database.

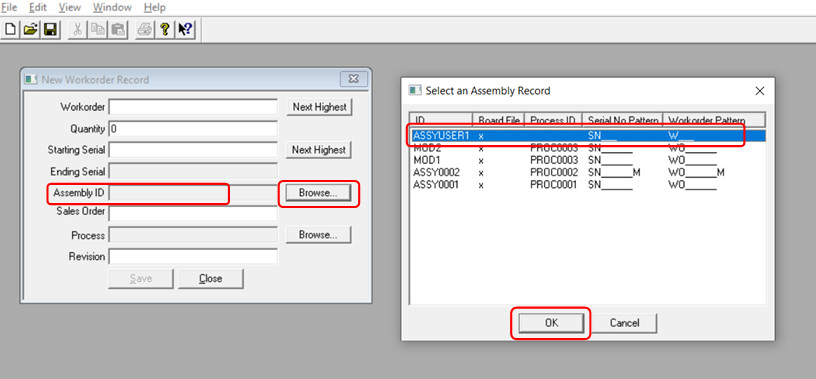

In the ASSEMBLY ID field click BROWSE and select the Assembly record ASSYUSER1 and click OK.

In the PROCESS field click BROWSE and select the Process ID record USER and click OK.

In the WORKORDER field click NEXT HIGHEST and the result is workorder number

W001.

For your product

routings you can call the Workorder whatever name you desire for any industry

you are in. For example: WO0001, PO04284, CUSTOMER-ABC, J124888-1,

320-00115-000, etc.

In the QUANTITY field type 10. In

the STARTING SERIAL field click NEXT HIGHEST. The result should look like the figure below.

Click SAVE. The Workorder is complete.

Note SALES ORDER and REVISION fields can be left blank.

3) Test the new process by running the route through the CELLS Workflow MES software:

What follows is the short version for this step "3) Test the new process by running the route through the CELLS Workflow MES software:" and below this short version is the detailed version with a step-by-step breakout and graphics of what is happening.

Short version:

Test the new process by running the route through the

CELLS Workflow MES software.

First start the CELLS Workflow MES Product Tracking software.

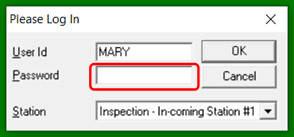

Click OK. MARY will be in the USER ID field and INSPECTION -

IN-COMING STATION #1 in the STATION field.

In the PASSWORD field type 4117 and click OK.

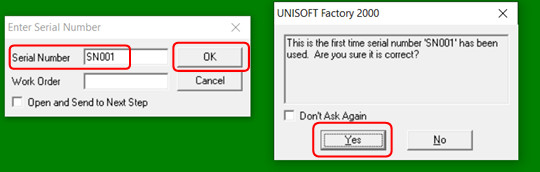

Next click FILE and OPEN SERIAL NUMBER. Type SN001 in hte

SERIAL NUMBER field, click OK. Then click YES again.

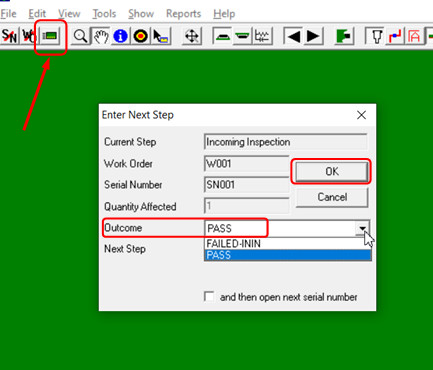

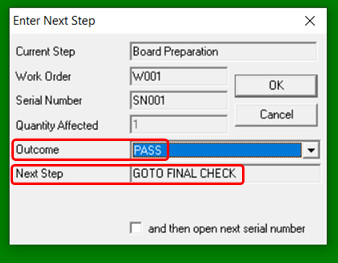

Next will move the unit to another step in the process. Click

the NEXT-STEP icon in the upper left of the display. In the OUTCOME field PASS

is the default, click OK.

Next we will open the Operation step PREP. Click FILE and

OPEN SERIAL NUMBER. Type SN001 in hte SERIAL NUMBER field, click OK. Then click

YES again.

Next will move the unit to another step in the process and it

will be the new Operation step we created earlier FINAL-CHK .

Click the NEXT-STEP icon in the upper left of the display. In

the OUTCOME field PASS is the default, click OK.

Next will move the unit to another step in the process. Click

the NEXT-STEP icon in the upper left of the display. In the OUTCOME field PASS

is the default, click OK.

So the result is for this test is that serial number SN001

in Workorder W001 has completed its Process USER routing that we created earlier

in the CELLS Route Builder.

-------------

Detailed version:

First start the

CELLS Workflow MES Product Tracking software.

In the Start/Programs Menu in the "CELLS WORKFLOW MES Product Tracking" folder

click

CELLS

Workflow MES Product Tracking.

Click OK. MARY will be in the USER ID field and INSPECTION - IN-COMING STATION #1 in the STATION field. In the PASSWORD field type 4117 and click OK.

Next click FILE and OPEN SERIAL NUMBER. Type SN001 in hte SERIAL NUMBER

field, click OK. Then click YES again.

In this step we opened a new serial number unit from the 10 serialize units SN001-SN010 we define earlier when we created Workorder W001.

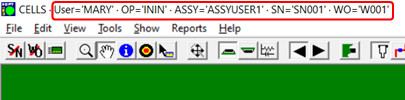

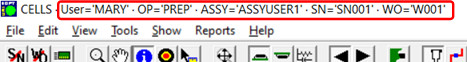

The unit in the route is displayed. The top of the display shows the route status of what is being worked on and for Workorder W001 for serial number SN001 the unit is at Operation step ININ.

Note the main display will have a default picture. You can have whatever picture you want at any step in the route displayed by indicating it in the DOCUMENTS table.

Next will move the unit to another step in the process. Click the NEXT-STEP icon in the upper left of the display. In the OUTCOME field PASS is the default, click OK.

In the previous step the Operation completed for serial number SN001 was ININ

and the unit was move to Operation PREP.

Next we will open the Operation step PREP. Click FILE and OPEN SERIAL NUMBER. Type SN001 in hte SERIAL NUMBER

field, click OK. Then click YES again.

The top of the display shows the route status of what is being worked on and for Workorder W001 for serial number SN001 the unit is at Operation step PREP.

Next will move the unit to another step in the process and it will be

the new Operation step we created earlier FINAL-CHK .

Click the

NEXT-STEP icon in the upper left of the display. In the OUTCOME field PASS

is the default, click OK.

Next will move the unit to another step in the process. Click the NEXT-STEP icon in the upper left of the display. In the OUTCOME field PASS is the default, click OK.

So the result is for this test is that serial number SN001

in Workorder W001 has completed its Process USER routing that we created earlier

in the CELLS Route Builder.

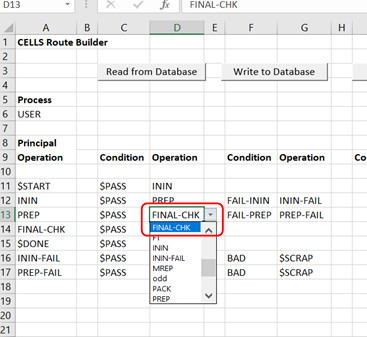

The figure below is the Process USER we created earlier on the FLOW tab of the

CELLS Route Builder.

Again all along the procedure outlined above you can enter your own information for your own product tracking as required. For help contact Unisoft and we can go online with you.

4) Database Tables that are edited directly.

MISC:

BRIEF EXAMPLE OF CHANGING AN EXISTING DESCRIPTION OF A PROCESS IN THE NEXT_STEP TABLE

You can use the CELLS Route Builder to change the description in the NEXT_STEP table of a process or you can create a description of a new process. Follow these steps for changing the NEXT_STEP table for a process:

1. Select the Flow sheet.

2. Click the Read from Database button.

3. Click the dropdown arrow in the cell under Process and select a process.

4. Click the Read from

Database button again. You

should see the relevant steps for the process displayed.

5. You can now change the

flow. For the most part, you can

treat the spreadsheet as you would any spreadsheet.

Specifically, you can repeatedly do the following:

a. Change an operation or a condition in a cell. There are three ways:

i. Click the cell, click the dropdown arrow for the cell, and select an operation/condition.

ii. Double-click the cell and type an existing operation/condition.

iii.Double-click the cell and type a new operation/condition. The Builder will prompt you for information that describes the new operation/condition.

b. Delete operations or conditions in one or more cells by selecting a range of cells and clicking the delete key.

c. Delete one or more entire rows.

d. Insert rows.

e. Cut and paste ranges and rows.

6. You have the option of

changing data in the other sheets in the workbook, namely CONDITIONS,

NEXT_STEP, OPERATIONS, and PROCESSES.

Any changes you make to these sheets will be reflected in the Flow

sheet.

7. When you are satisfied

with the state of the description of the steps in the process, click the

Write to Database button to save the data.

Changes to data in

any of the sheets will be written to the database.

BRIEF EXAMPLE OF ADDING A NEW DESCRIPTION OF A PROCESS IN THE NEXT_STEP TABLE

Follow these steps for adding a new process description to the NEXT_STEP table:

1. Select the Flow sheet.

2. Click the Read from Database button.

3. Double-click the cell under Process and enter the name of a new process. The Builder will prompt you for information about the process.

4. The Builder does not change any data on the spreadsheet after you enter a process name. In this way, you can use data from a previously displayed

process, for example, as a starting point in describing the new process.

5. You can now create the

flow. For the most part, you can

treat the spreadsheet as you would any spreadsheet.

Specifically, you can repeatedly do

the following:

a. Add or change an operation or a condition in a cell. There are three ways:

i. Click the cell, click the dropdown arrow for the cell, and select an operation/condition.

ii. Double-click the cell and type an existing operation/condition.

iii.Double-click the cell and type a new operation/condition. The Builder will prompt you for information that describes the new operation/condition.

b. Delete operations or conditions in one or more cells by selecting a range of cells and clicking the delete key.

c. Delete one or more entire rows.

d. Insert rows.

e. Cut and paste ranges and rows.

6. You have the option of

changing data in the other sheets in the workbook, namely CONDITIONS,

NEXT_STEP, OPERATIONS, and PROCESSES.

Any changes you make to these sheets will be reflected in the Flow

sheet.

7. You have the option of

changing data in the other sheets in the workbook, namely CONDITIONS,

NEXT_STEP, OPERATIONS, and PROCESSES.

Any changes you make to these sheets will be reflected in the Flow

sheet.

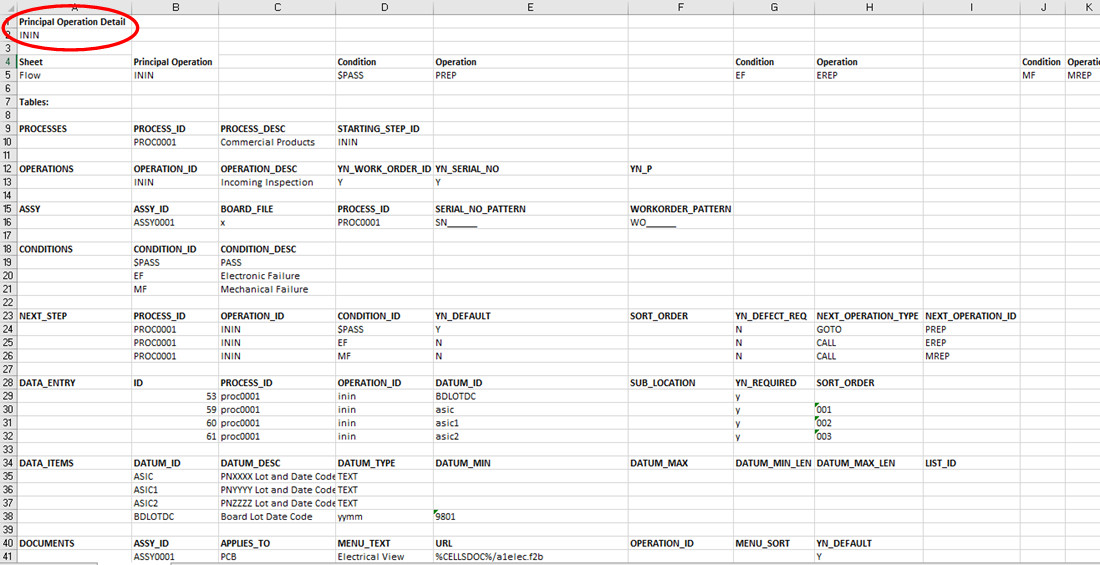

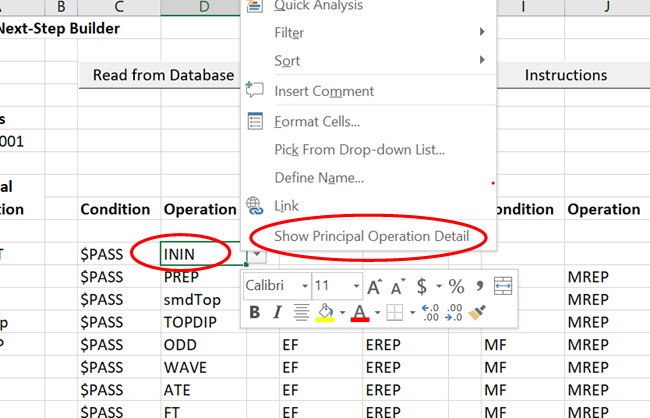

To show the detail on the Operation, right-click anywhere in a row in the spreadsheet. On the dropdown menu that displays, click on the last

item, which should be "Show Principal Operation Detail."

A new Excel spreadsheet will open with more detail on the

Operation.