Skip navigation

For over 40 years, Intelligent PCB Manufacturing

Automation Software

Be production ready in minutes, not days.

The Unisoft software can quickly export the package shape for each component and part number on the PC Board along with the center XY to program Assembly, AOI and other electronic manufacturing production machines and process.

Usually the problem that the engineer is presented with is that the part number and its associated components (reference designators) in the Bill Of Material (BOM) are not associated with the correct electronic component package shapes to program their Assembly, AOI and other equipment. This can be time consuming for OEM manufacturers and especially EMS electronic contract manufacturers where they have to contend with a multitude of part numbers supplied by their customers.

The Part Number encompasses the complete component information "Form / Fit / Function" and the Package Shape pertains only to the "Form / Fit" of the component. So what needs to be accomplished is from the BOM associate the part number with the component (reference designators) and then associate this with the package shape. No matter who the supplier of the software is that will program the machine(s) these associations need to be made.

With the Unisoft software the part number and components are automatically associated when the BOM is imported. Then for new part numbers without the package shape the association is made only once and then can be saved by the software and when the part number is used again in the future the software will associate the package shape automatically.

The Unisoft software then exports the correct Assembly, AOI or other machine programming file with the Part Number, Component, Package Shape, X/Y, etc. to run the PC Board.

In addition to the package shape other information can be stored and then imported such as feeders, nozzles, assembly instructions, etc.

There are 3 methods that follow to get the package shape to program the Assembly, AOI, etc. equipment.

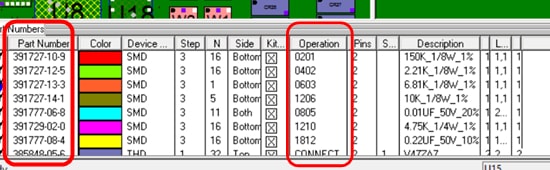

Method 1: This is the most common method which is to create a Part Number and Package Shape library.

Example library:

390222-07-1 0402 390222-06-2 0201 390579-03-3 SOT23 395422-01-9 SOIC8 391829-03-3 SOIC20 391809-01-6 PLCC20

For this simple ASCII library file there are only 2 fields the part number and the package name separated by a tab and it can contain as many part numbers as desired. Also any number of libraries may be created.

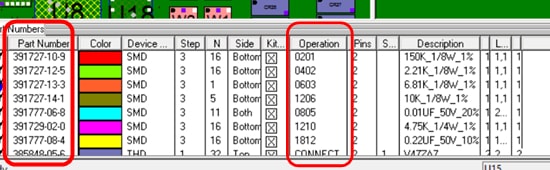

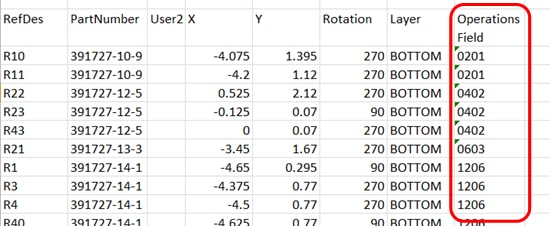

The library is then imported and any matching part numbers on the PC Board are assigned the shape found in the library and that shape is then listed in the Operations field on the Unisoft display.

The next time any part number in the library is used again on subsequent PC boards then their package shapes will be automatically imported into the Operation field.

Next the Operation field is exported into the file created to program the Assembly, AOI and other production machines.

Note for assembly or other machines that need other information such as feeder and nozzle information which is sometimes the case for older assembly machines this information can also be handled using a Unisoft library.

Example library:

391727-10-9 Juki feeder NF4MM / Juki nozzle 502 391727-12-5 Juki feeder NF4MM / Juki nozzle 502 391729-02-0 Juki feeder NF8MM / Juki nozzle 504 391777-08-4 Juki feeder NF16MM / Juki nozzle 507 390579-03-3 Juki feeder NF32MM / Juki nozzle 509 385848-05-6 Contact Systems CS400 seq=1 / (note: this diode modeled 180 degrees off w/anode=pin 1) 381212-44-1 Contact Systems CS400 seq=2 / LED - clinch angle special=5 386754-99-4 Contact Systems CS400 seq=3 / 389148-06-7 Contact Systems CS400 seq=4 / clinch angle special=5 396051-01-4 Contact Systems CS400 seq=5 /

This library can then be imported using method #1 above. Also this feeder, nozzle and other information can be inserted using the methods below.

More information: How to create an Operation library and assign the Operations to part numbers.

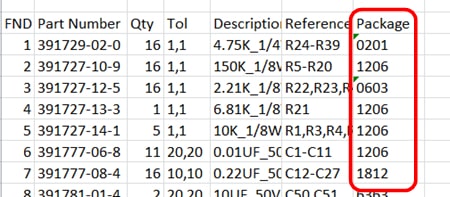

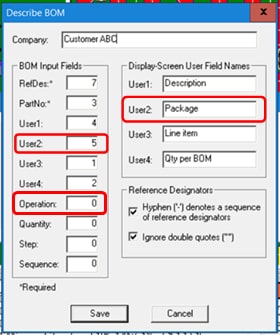

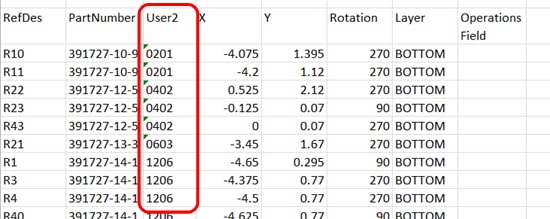

Method 2: If the correct package sizes are in a column in the BOM

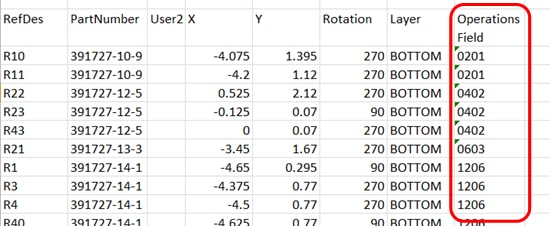

then you can simply import that column through the BOM importer by either using the User2 import field or the Operation import field.

Then those package shapes will be automatically exported to the file that the Unisoft software creates to program the Assembly, AOI and other equipment.

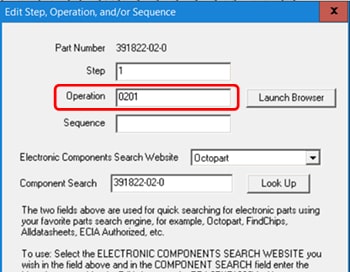

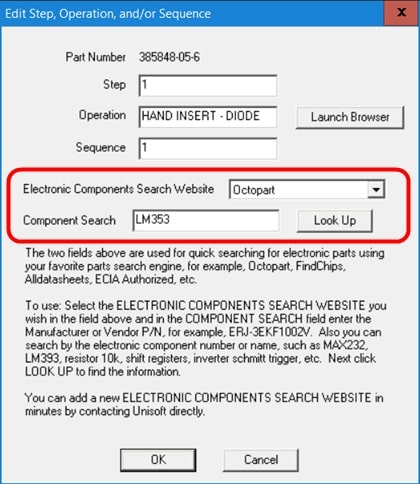

Method 3: You may manually enter or edit the part shape information into the "Edit Step, Operation…" window.

This information is then displayed in the Operation field.

Then that Operation data is exported to the machine programming file created by the Unisoft software.

This information that is manually entered can then be saved to a library file for future use.

390222-07-1 0402 390222-06-2 0201 390579-03-3 SOT23 395422-01-9 SOIC8 391829-03-3 SOIC20 391809-01-6 PLCC20

A helpful feature of the Unisoft software to determine the package shape, etc. is available to aid in looking up that information.

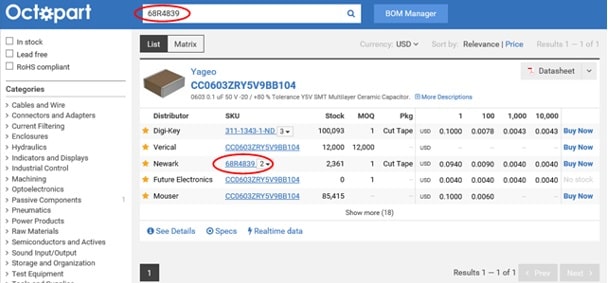

You can lookup the component shape information and more via Digikey, Octopart, Findchips, etc. Components can be searched by vendor part number or electronic component number or name.

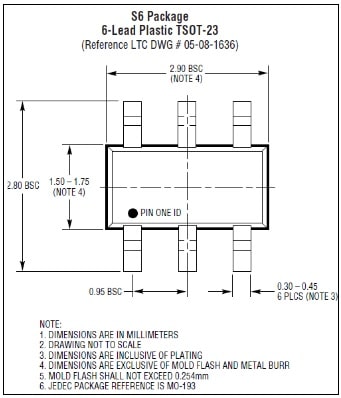

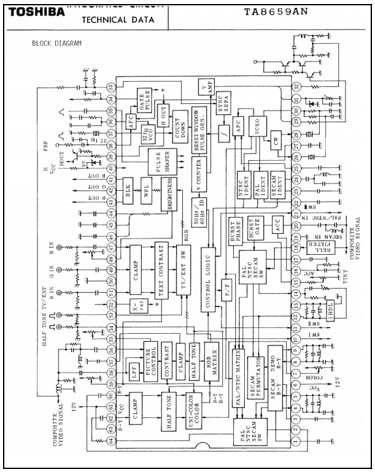

The result is component information such as part footprint shape, electrical specifications, cost, availability, etc. is displayed.

The component footprint dimensions (correct solder pad size and land pattern) can be found.

Also the internal electronic functionality, etc. can be searched.

For further details on features and operations contact Unisoft directly. Or from the Start Menu or from where you installed the Unisoft software please review the manual by clicking the "Pronto… Quick-Start Manual" in the Unisoft folder.