Skip navigation

For over 40 years, Intelligent PCB Manufacturing

Automation Software

Be production ready in minutes, not days.

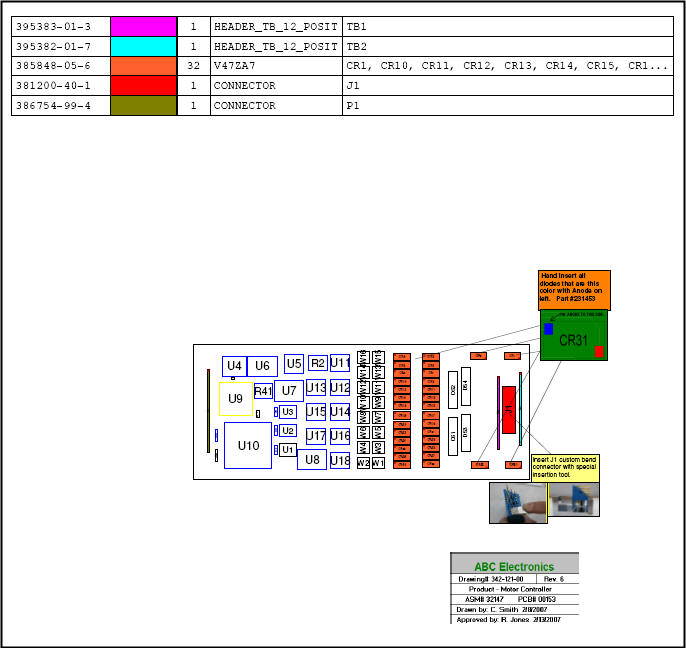

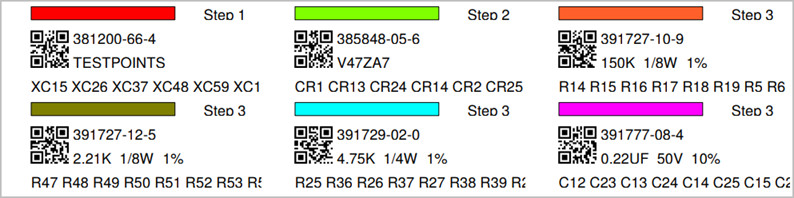

Creating assembly process or inspection documents is straightforward using Unisoft software. Component part numbers can be broken down into steps, with unique colors and brush patterns assigned to each part number. This allows for the creation of assembly or inspection process documents and kitting labels of various types, a sample of which is shown in the following two figures.

The following process

outline provides a brief overview of creating process assembly or inspection

documents. It assumes some basic working knowledge of the software, so

certain fundamental steps will not be detailed.

For more details than those outlined below, contact

Unisoft or refer to the manual section "Tutorial 1 — Creating assembly/process

sheets, annotation overlays, and kitting labels" by

clicking here

and following the procedure outlined.

There are basically four steps to creating assembly or inspection documents:

Step 1. For the process outlined here we are using the sample3.f2b board data file located in the directory c:\program files (x86)\unisoft\data-files . You can open that PCB file if you wish.

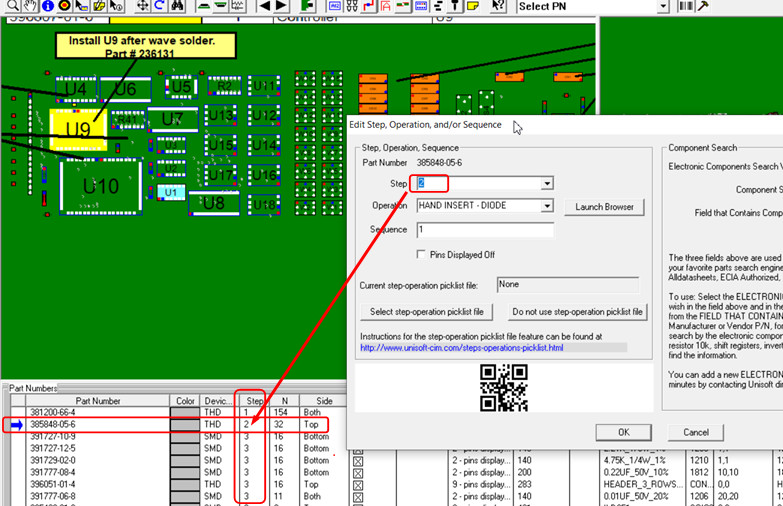

Next for our sample PCB assembly in the figure below,

Step 1 is assigned to the first part number, Step 2 to the second part number,

and Step 3 to the remaining part numbers.

As illustrated in the

figure below, this is done by double clicking on the part number in the

Smart Color window at the bottom of the display, then in the "Edit Steps,

Operations, and/or Sequence"

window, edit the "Step" field to

the desired number. Click "OK" when finished.

If desired, you can

further add Substeps to these steps to further breakdown these operations.

Note: When a PCB is first imported into the Unisoft software all part numbers are assigned to Step 1.

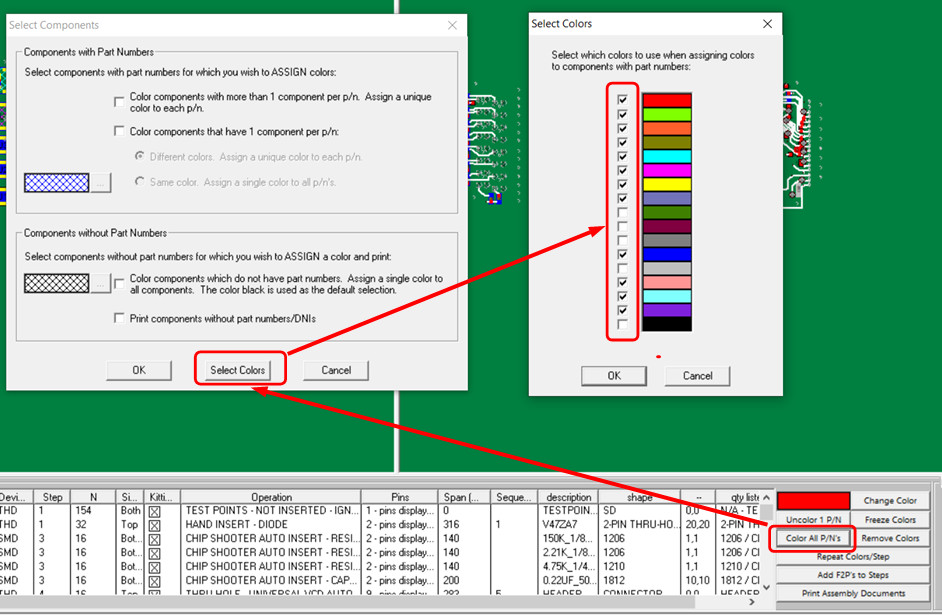

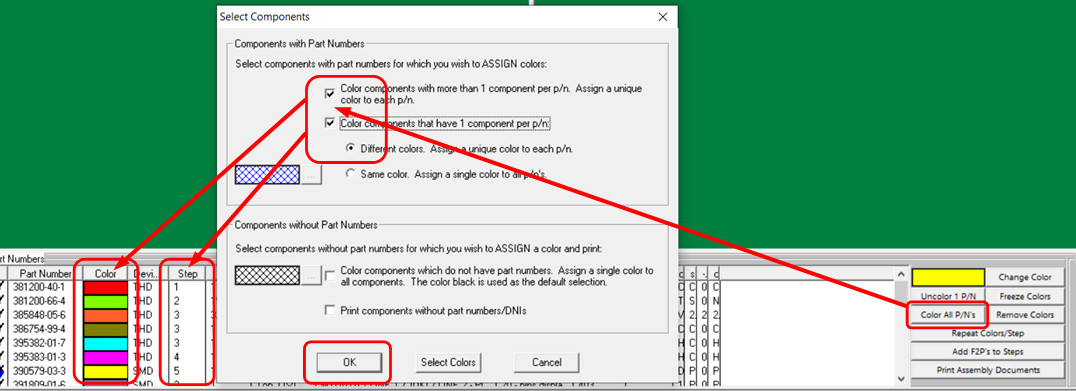

Step 2. At this point, either automatically or manually assign colors and brush patterns to part numbers and components.

Before the colors and brush patterns are assigned to the part numbers and components, you

can choose which ones you wish to use. To do this, as in the picture

below, first click "Color All P/N's" then click "Select Colors/Brush

Patterns". In the "Select Colors/Brush Patterns" window, select the colors

and brush patterns you want by

checking or unchecking the boxes desired. Click "OK" when finished.

Now, in our sample PCB in the figure below, the colors and brush

patterns are assigned automatically, so red is assigned to Step 1, green to

Step 2, and so on. To do this, first click

"Color All P/N's,"

then in the "Select Components" window, click the assign

color settings that you wish (use the settings in the picture below), and then click "OK". The colors and brush

patterns are then assigned to

the part numbers and components.

Note: Components without part numbers, usually referred to as Do Not Install

(DNI) components, are colored black by default when the "Color Components

Which Do Not Have Part Numbers..."

box is checked.

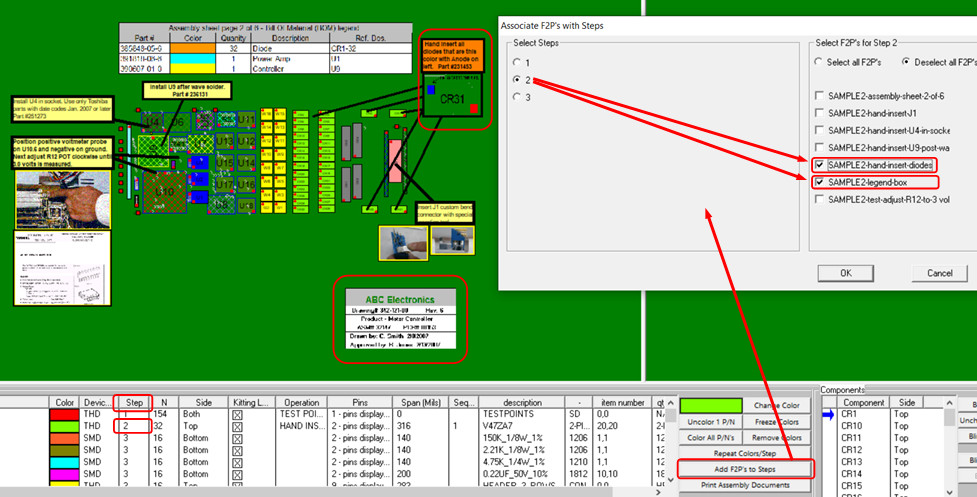

Step 3. Optionally add annotation overlays to

steps. For example, in the figure below, the annotation overlays named

"SAMPLE2-hand-insert-diodes" and "SAMPLE2-legend-box", that are outlined

in red

on the image below, are assigned to Step number 2. So, when Step 2 is printed,

only these two annotation overlays will appear on that step.

To do this, as illustrated in the figure below, click on "Add F2P's to Steps".

In the "Associate F2P's with Steps" window, select the step and then the desired

overlay .F2P document or documents you

wish to be displayed at that step.

Click "OK" when finished.

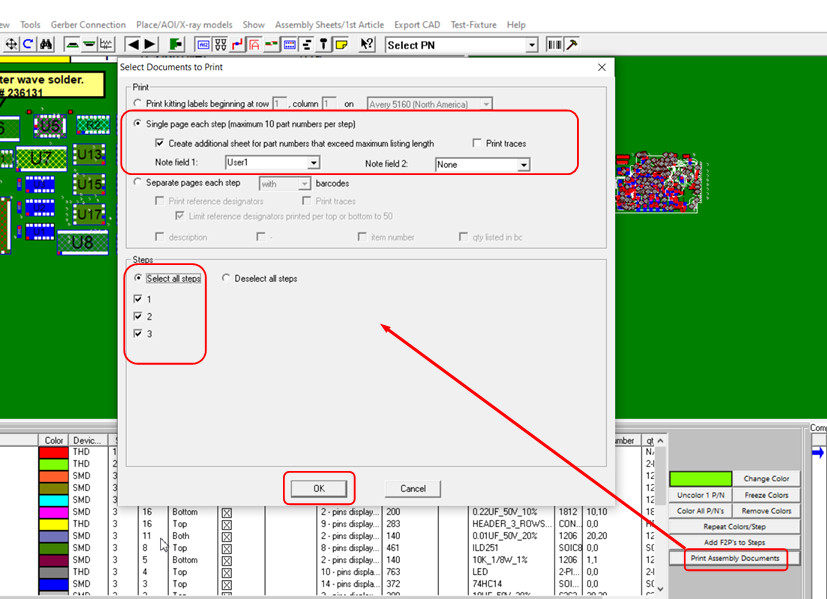

Step 4. Print out the assembly document using

the format shown in the figure below by selecting all steps and choosing the

"Single page each step..." option. Note, this

"Single page each

step..." format, while less detailed, is popular because it combines the

drawing and assembly load list on a single page for each step, making it

visually efficient for assembly operators.

To do this, first click

on "Print Assembly Documents" as shown in the picture below. Next, use the

settings illustrated in the figure below in the "Select Documents to Print"

window. Click "OK"

and choose the desired printer format, for example, print to

a PDF document, printer, etc.

If desired,

PCB photos,

gerber silkscreen overlays, part number

barcodes, and other options can be added to the documents.

Note: There are several options for different types of process documents

that can be created. For example, the

"Separate pages

each step" option in the "Select Documents to Print" window creates a

process document with more detail but more pages. Another

example is using

Microsoft Powerpoint to create the process document.

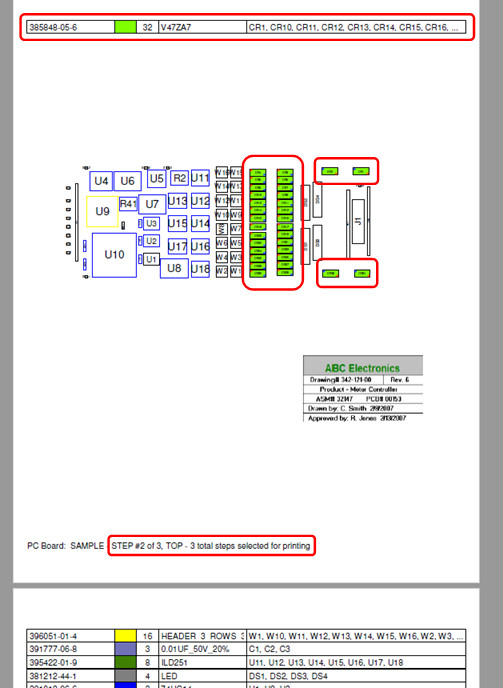

The assembly document created contains all three steps with unique

colors. For example, as can be seen in the figure below, for Step 2 in the

printout, the part number was assigned the color green, and all the components

with that part number are colored green.

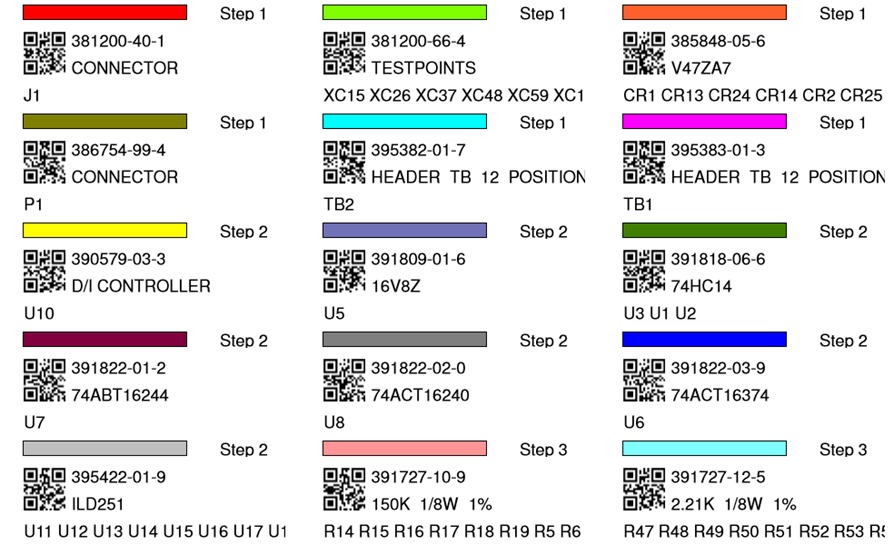

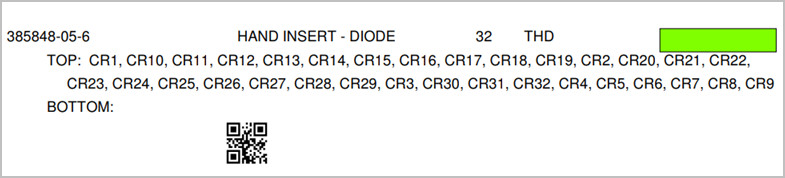

Matching kitting label documents of various types can

be created, as illustrated in the following two figures.

To do

this in the second figure above in the "Select Documents to Print"

window select "Print kitting labels beginning at row...". Then click

"OK" and choose the desired printer format,

for example, print to

a PDF document, printer, etc.

Additional similarly related Information:

Assembly documents - adding steps to part numbers

Assembly documents -

adding substeps to part numbers

Assembly documents -

manual "tutorial 1 - creating assembly/process sheets, annotation overlays and kitting labels"

Assembly

documents - printing assembly documents

Assembly documents - creating kitting labels

Assembly documents -

kitting labels-1

kitting labels-2

kitting labels-3

Assembly documents - single page per step.

Assembly documents - multiple pages per step

Assembly documents -

powerpoint and custom types

Assembly

documents - editing multiple assembly steps

Assembly documents - add pcb photos, etc. to the display background

Assembly documents -

for paperless assembly instructions when using the display only for slide

line pcb assembly, etc.

Barcodes on the display and assembly

documents