Skip navigation

For over 40 years, Intelligent PCB Manufacturing

Automation Software

Be production ready in minutes, not days.

A printed circuit board (PCB) component is an electrical part that goes into

making the assembly of a circuit board. There may also be non-electrical parts

and services

needed for the assembly of the PCB.

PCB electrical components consists

of elements such as diodes, capacitors, fuses, resistors, IC's, etc.

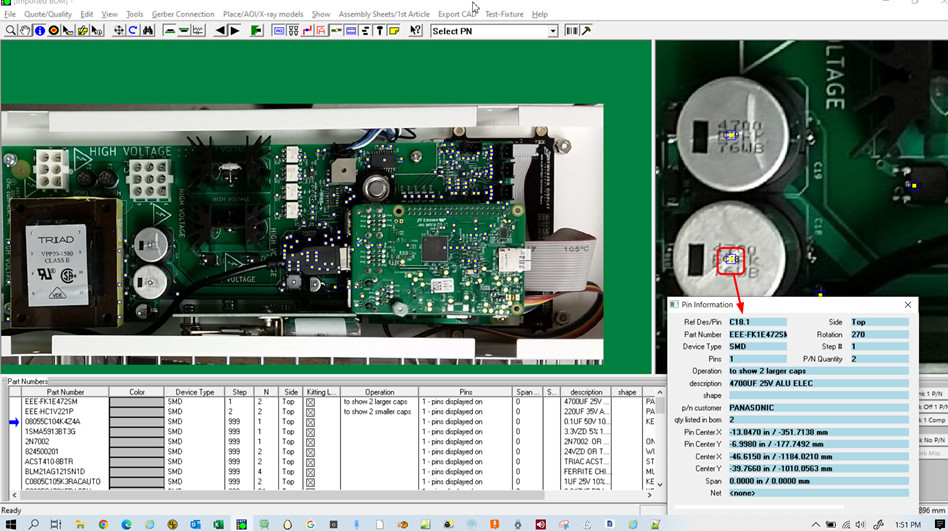

The

Unisoft software matches these electrical components defined in the PCB file

data which can be CAD files, Gerber files or XY center rotation files with the

electrical components listed in the Bill Of Material (BOM).

The names

for the matching electrical components on the PCB and BOM data files are

normally referred to as "reference designators".

The assembly of a PCB

may include non-electrical components such as board stiffeners, sockets, heat

sinks, stand-offs, push button caps, spacers, and additional services such as

AOI inspection and Flying Probe Testing, among others. Since these

non-electrical items in the BOM do not typically have a matching reference

designator in the PCB file data, they are not included in the Unisoft Pronto

software when the PCB is displayed.

Below are several methods and ideas for incorporating these non-electrical items

into the Unisoft Pronto software when displaying the PCB, enabling the handling

of these processes and the calculation of their costs. It is assumed you have some experiance using the Unisoft software,

contact Unisoft for training if needed.

NOTE:

On this webpage we are discussing how to add non-electrical parts listed in the

Unisoft Pronto series software (modules include ProntoVIEW-MARKUP, ProntoPLACE, ProntoAOI,

ProntoTEST-FIXTURE, ProntoSELECTIVE-SOLDERING and ProntoGERBER-CONNECTION) and

the methods listed below are usually adequate for most Electronic Manufacturers

to handle and cost these non-electrical parts during the assembly process. However

Unisoft has another software module called Unisoft CELLS MES Tracking software (

https://www.unisoft-cim.com/cells.php ) which is meant to do more complex

functions with PCB board and box build and maybe a consideration for some

Electronic Manufacturers for the handling of these non-electrical parts on the

PCB.

With the Unisoft Pronto series software a simple way to handle non-electrical

parts for assembly is to add pictures or any type of overlay with text, etc.

that may represent these non-electrical parts.

Link -

https://www.unisoft-cim.com/view-markup_download.htm#CREATING_.F2P_ANNOTATION_OVERLAYS

.

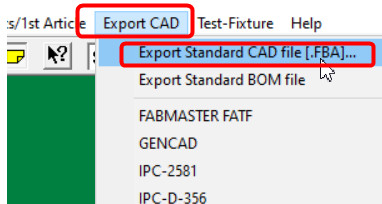

In this method the non-electrical parts are added to the exported Unisoft .FBA data file. The process in brief is:

- Import the PCB as normal into the Unisoft software.

- Export a .FBA file.

-

To the .FBA file add the non-electrical parts as a dummy line entry. For

example board stiffeners or stand-offs, push button caps, spacers, sockets,

heat sinks,

etc.

- Reimport the .FBA file into the Unisoft software.

-

Import the BOM including the

non-electrical parts. Now these non-electrical parts have an

association in the Unisoft software similar to the electrical components.

note: each non-electrical part, you wish included, needs to have a unique

name in the BOM.

More detail for

this method follows. This process can be relatively quick maybe 5 to

10 additional minutes for a project.

In this method to add

non-electrical parts that are in the BOM first import your standard

type CAD data as you would normally. Then export out a .FBA file which

contains data that represents the PCB just imported.

Example .FBA:

*XY

1 - -RDLTCH U5 3 X -4.600

Y 2.000 T S

1 - -RDLTCH U9 40 X -5.425

Y 1.675 T S

At this

point in the .FBA file you would edit in the reference designators for the

non-electrical parts, for example for board stiffeners or stand-offs, push

button caps, spacers, sockets,

heat sinks,

etc. and you would use the same reference designator names for them that are

used in the BOM (Note:

each non-electrical part, you wish included, needs to have a unique name in

the BOM.).

Each non-electrical part added is inserted in a line on its own. The

only data in the line that needs to be unique is the non-electrical parts

reference

designator you are adding.

So you can

default using the same dummy type data in the fields in each line added.

For example the fields in red below can be repeated on each line:

9999, -, XXXXXX, 1, X, 0.000, Y, 0.000, T. So for each

line added enter

only the unique reference designator for the

non-electrical

parts as they are defined in the BOM as has been done with the 4 red

lines in the sample below.

*XY

1 - -RDLTCH U5 3 X -4.600

Y 2.000 T S

1 - -RDLTCH U9 40 X -5.425

Y 1.675 T S

9999 - XXXXXX

SOCKET1 1 X

0.000 Y 0.000 T

9999 - XXXXXX

SOCKET2 1

X 0.000

Y 0.000

T

9999 - XXXXXX

STDOFF1 1 X

0.000 Y 0.000 T

9999 - XXXXXX

PUSHB1 1 X

0.000 Y 0.000 T

9999 - XXXXXX

PUSHB2 1 X

0.000 Y 0.000 T

9999 - XXXXXX

SPACE1 1 X

0.000 Y 0.000 T

9999 - XXXXXX

AOI-INSPECTION-SERVICE 1 X

0.000 Y 0.000 T

9999 - XXXXXX

FLYING PROBE-TESTING-SERVICE 1 X

0.000 Y 0.000 T

Next

import the .FBA file into the Unisoft software as you would any other CAD

data file. At that point these new reference designators are part of the

Unisoft .F2B database created for this PCB.

Next import the BOM as

normal and the newly introduced

non-electrical

items reference designators will be associated to the bom data for

those reference designators.

Again each non-electrical item, you wish included, needs to have a unique

name in the BOM.

At this point you can add

any picture graphics, text, etc. as you normally would to enhance the

assembly instructions.

Also these new non-electrical parts can

be assigned a cost, their own process step number, unique coloring, operation note information,

etc.