Skip navigation

For over 40 years, Intelligent PCB Manufacturing

Automation Software

Be production ready in minutes, not days.

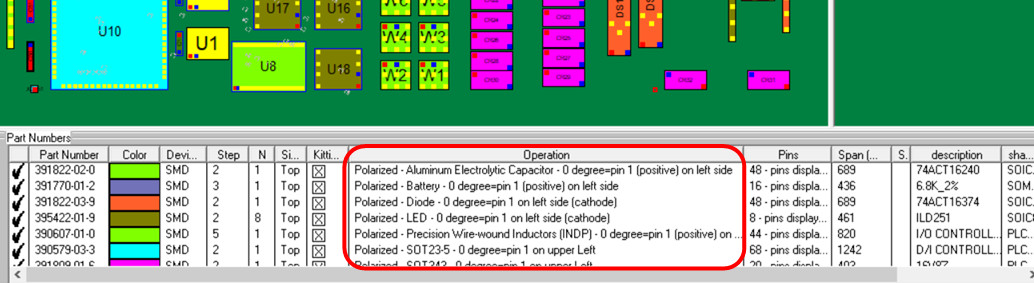

Use the Library to mark part numbers — for example, this can include

polarized components, "do not install" (DNI) parts, or other special

component operations.

A simple way to highlight part numbers and

their components that need to be inspected or assembled is to maintain a

Library containing your polarized or other special part numbers. You then

import that Library against the PCB that is being worked on. The

Operation field will be

automatically filled in with instructions on what to do. [Link

to library creation information.]

The library file might look like the following:

390222-07-1 Polarized - Diode - 0 degree=pin 1 on left side (cathode) 390579-03-3 Polarized - Capacitor - 0 degree=pin 1 (positive) on left side 395422-01-9 Polarized - LED - 0 degree=pin 1 on left side (cathode) 391822-02-0 Polarized - Aluminum Electrolytic Capacitor - 0 degree=pin 1 (positive) on left side 391822-03-9 Polarized - Diode - 0 degree=pin 1 on left side (cathode) 391818-06-6 Polarized - Tantalum Capacitors - 0 degree=pin 1 (positive) on left side 391809-01-6 Polarized - SOT343 - 0 degree=pin 1 on upper Left 390607-01-0 Polarized - Precision Wire-wound Inductors (INDP) - 0 degree=pin 1 (positive) on left side 390579-03-3 Polarized - SOT23-5 - 0 degree=pin 1 on upper Left 390222-06-2 Polarized - SOT23-3 - 0 degree=pin 1 on upper Left 385848-05-6 Polarized - Zener Diode - 0 degree=pin 1 on left side (cathode) 391770-01-2 Polarized - Battery - 0 degree=pin 1 (positive) on left side

Note: There can be as many

Library files as desired, and the example Library file above can contain an

unlimited number of part numbers. The part numbers listed above, such as

390222-07-1,

390579-03-3, etc., in this

example Library are in-house and not standardized part numbers.

Where

possible, it's best to use part numbers linked to a standard, such as the

Manufacturer Part Number (MPN). For example, these are MPNs:

CC0402CRNPO9BN2R2,

RC0201JR-0710RL,

DS520-30EAA02. The MPN is a

unique code used to identify different component parts, and it is

standardized and universally recognized.

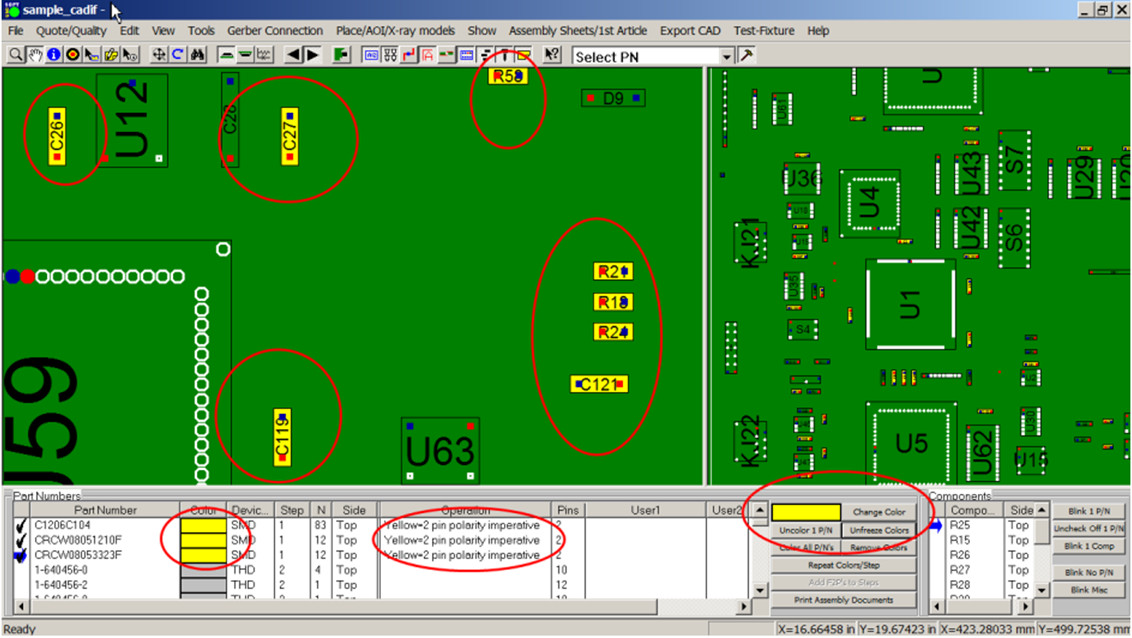

After the Library is

imported, the Operation

field in the Smart Color

window at the bottom of the display will appear as shown below. The

Operation field will be filled in with instructions on what to do.

Components for each part number can be blinked and listed on the display and

acted on accordingly, or they can be color-coded, assigned a step number,

and printed.

This method within the Unisoft software allows users to selectively

turn component pins on or off by part number, making polarized and "Do Not

Install" (DNI) components stand out for inspection or assembly. Below is an

outline of how this feature operates, along

with other methods that can

achieve similar results.

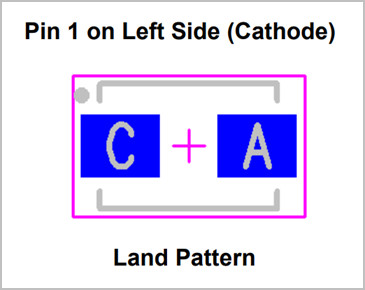

Note:

When checking polarized parts, it is essential to ensure that their 0°

rotation has been set according to a recognized standard. The key constraint

in identifying polarized parts is that the part itself must have been

modeled based on a known specification.

For example, the figure below

shows a diode component modeled according to the IPC-7351B Level A standard,

with 0° rotation defined as left-oriented, where the cathode (Pin 1) is on

the left. If the CAD file does not follow any known standard—such

as

when the PCB was designed using a smaller CAD system by a non-expert

designer, or if it is an older legacy design from a time when standards were

less stringent—then it's possible there may be no reliable reference point

for a known 0° rotation.

Although there has been progress in recent

years, a universal global standard for 0° component rotation does not yet

exist. However, the IPC-7351B Level A standard is currently the most widely

accepted, and it is the standard used by Unisoft software when

calculating 0° component rotation.

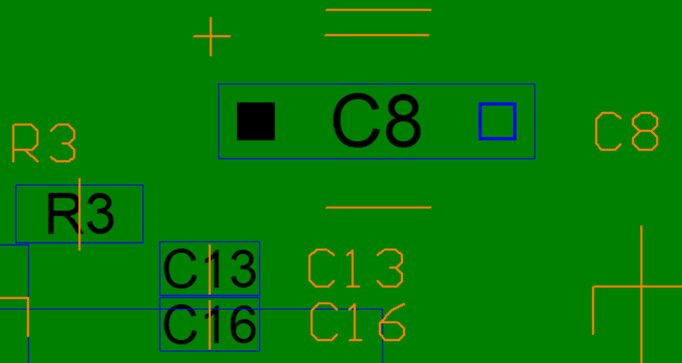

In the figure below, C8

is a polarized component, and the pins on that device have been left

ON to aid polarity

inspection and identification. The components

R3,

C13, and

C16 are non-polarized, and

the pins on those devices have been turned

OFF because they do not

require polarity inspection.

This feature—turning selective part numbers and their respective component pins on or off on the display—is useful in several areas of electronic manufacturing.

One example is the inspection of

polarized components. In this case, the user would direct the Unisoft

software to turn off all

pins on components that are not

polarized, allowing the polarized components to stand out and be easily

identified for inspection.

The inspection can then be performed directly

from the current display, or the components can be printed on an inspection

document.

Another example involves

selective components on the PC board that require hand assembly. In this

case, only those components would be displayed, with all others turned off,

simplifying the assembly process. The assembly can be performed either from

the current

display or by printing the components to an assembly

document.

There are two methods in the Unisoft

software for selectively turning component pins on or off by part number.

The first method is by selecting the EDIT STEP... window and toggling the PINS DISPLAYED OFF box accordingly.

The second method is by using a Library OPR file to specify particular part numbers for which the pins should be turned on or off.

The procedures for using these two mechanisms are outlined below. It is assumed that you have a working knowledge of how to use the Unisoft software. If you require training, please contact Unisoft directly

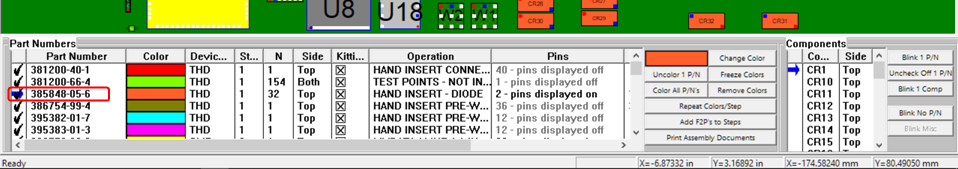

How to use the EDIT STEP method:

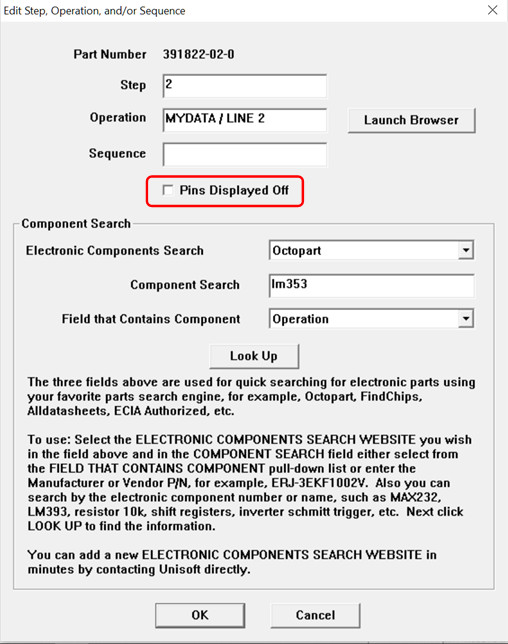

Open the SMART COLOR window at the bottom of the display, then double-click the part number you wish to edit.

The EDIT STEP, OPERATION... window opens, and you can toggle the PINS DISPLAYED OFF feature box accordingly. By default, this box is unchecked, so initially, the pins for all part numbers and components will be displayed on the PCB.

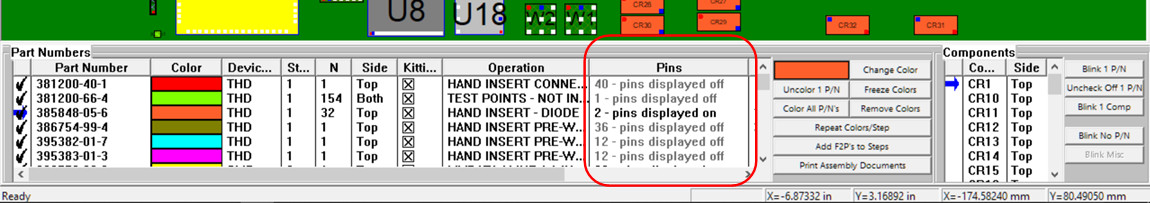

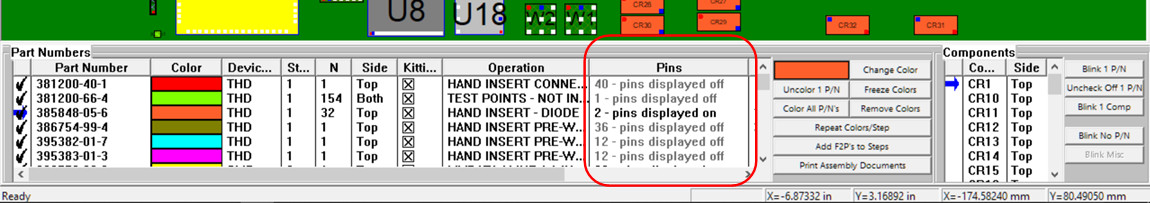

As the part numbers for component pins are turned on or off in the SMART COLOR window, the PINS field will reflect their status as either PINS DISPLAYED ON or PINS DISPLAYED OFF. If the state is PINS DISPLAYED OFF, it will appear dimmed in the SMART COLOR window.

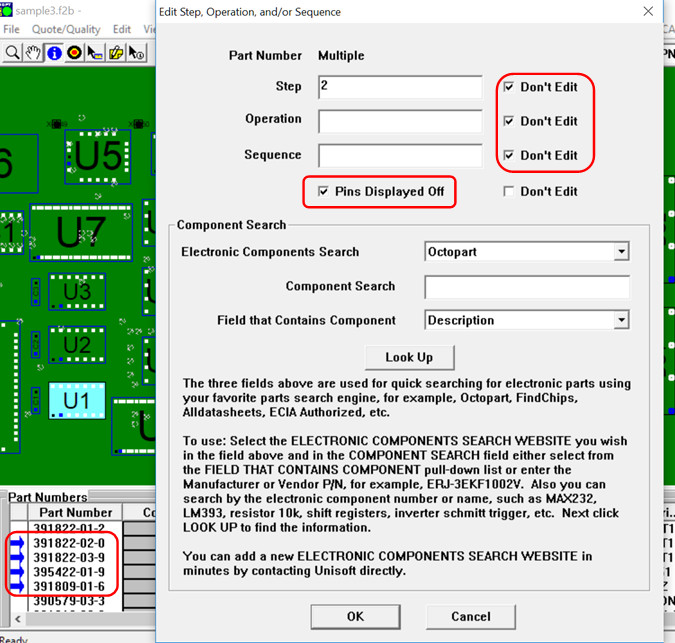

Note: Another feature of the SMART COLOR window is that you can select multiple part numbers to quickly toggle the pin states of those components OFF or ON. To do this in the Unisoft software, use the Ctrl key to select more than one part number individually, or select a range of part numbers using the Shift key.

How to use: In the SMART COLOR window, use the Ctrl key to select multiple part numbers one at a time, or use the Shift key to select a range of part numbers. Then, right-click on one of the selected part numbers, and the EDIT STEP, OPERATION... window will appear, allowing you to edit all selected part numbers at once.

In the figure below, in the lower left, four sequential part numbers outlined in red have been selected. To turn the pins OFF, the PINS DISPLAYED OFF box is checked. To prevent the editing of other fields, the three DON'T EDIT boxes are also checked. The result is that all the pins for all components of those four part numbers will be turned OFF on the display..

Use Example 1:

There are times when you will want to mark a whole group of part numbers to the

PINS DISPLAYED OFF state

quickly, and the feature described above will help you do that. For example,

usually polarized components are the minority of components on the PCB assembly

(PCBA), and since the initial default state for all component pins is

ON, the fastest way to set the

display up properly is to first turn all part numbers and their component pins

to OFF, and then either

singularly or via the OPR operations

file turn ON the minority part numbers you want displayed.

Use Example 2:

Most of the time, the information on which components to turn ON or OFF on the

display is either in the Bill of

Materials (BOM) or in an OPR

operation file, both of which can be quickly imported into the Unisoft

software. You can simply sort on any field in the

SMART COLOR window and then

group part numbers as either ON

or OFF on the display as

desired. For example, if the BOM or OPR file indicates which part numbers are

polarized, then those part number component pins can be turned

ON on the display for easy

inspection.

How to use the library .OPR file method:

Create an

.OPR library file with

the part numbers you wish to edit.

To

automatically turn OFF

all the component pins for all the components in a part number, use the

following command in the second field:

= $PinsDisplayedOff

To automatically turn ON

all the component pins for all the components in a part number, use the

following command in the second field:

= $PinsDisplayedOn

Example of an OPR library file:

385848-05-6 $PinsDisplayedOff 391781-01-4 $PinsDisplayedOff 381212-44-1 $PinsDisplayedOff 390607-01-0 $PinsDisplayedOn 390579-03-3 $PinsDisplayedOn 395422-01-9 $PinsDisplayedOn

The default condition is that, initially, for all part numbers and all components, the pins are displayed on the PCB.

Next, import the OPR library file by clicking the FILE menu, then selecting IMPORT LIBRARY (.OPR)..., choosing the library you created, and clicking OPEN. The result is that the pins for the components on the PCB assembly (PCBA) will be turned OFF or ON accordingly.

In the SMART COLOR window, the PINS field will represent them as either PINS DISPLAYED ON or PINS DISPLAYED OFF. If the state is PINS DISPLAYED OFF, it will appear dimmed in the SMART COLOR window.

A simple example is to create a library with your polarized

components in it, import that library, and then turn the pins OFF for

all components that do not have a polarized notation in the

Operation field. As a

result, the components that remain

with pins ON in the display will

be the polarized components to be inspected. [Link

to library creation information.]

The library file might look like the following:

390222-07-1 Polarized - Diode - 0 degree=pin 1 on left side (cathode) 390579-03-3 Polarized - Capacitor - 0 degree=pin 1 (positive) on left side 395422-01-9 Polarized - LED - 0 degree=pin 1 on left side (cathode) 391822-02-0 Polarized - Aluminum Electrolytic Capacitor - 0 degree=pin 1 (positive) on left side 391822-03-9 Polarized - Diode - 0 degree=pin 1 on left side (cathode) 391818-06-6 Polarized - Tantalum Capacitors - 0 degree=pin 1 (positive) on left side 391809-01-6 Polarized - SOT343 - 0 degree=pin 1 on upper Left 390607-01-0 Polarized - Precision Wire-wound Inductors (INDP) - 0 degree=pin 1 (positive) on left side 390579-03-3 Polarized - SOT23-5 - 0 degree=pin 1 on upper Left 390222-06-2 Polarized - SOT23-3 - 0 degree=pin 1 on upper Left 385848-05-6 Polarized - Zener Diode - 0 degree=pin 1 on left side (cathode) 391770-01-2 Polarized - Battery - 0 degree=pin 1 (positive) on left side

Additional method: Use color-coding to identify component

groups (e.g., assembly step groups,

polarized components) in order

to aid assembly, rework, and inspection

For coloring components to assist with assembly and

inspection—such as identifying polarized components—you can assign a

single color to all part numbers that are polarized. For example, in the

example below, we have used yellow. You can also optionally add a note

and

associate it with a step number. In the example, we used the

note "Yellow = 2 pin polarity

imperative" and placed the three part numbers colored yellow in

step #1. Note:

assigning a step number is optional.For coloring components for assembly

aids inspection aids etc.

To apply the color:

Click on the part number you wish to color in the SMART COLOR window at the bottom.

Click the "Color 1 P/N" button.

Then click the "Change Color" button and select the color you want.

Once you have colored all the desired part numbers:

Click "Freeze Color" to freeze the colors on the display.

If desired, you can print these out. If a unique step number is used, all yellow-colored components will print on a single sheet. Alternatively, if you do not wish to print, you can simply use the "Blink 1 P/N" button on the screen to visually highlight part numbers and aid assembly and inspection.

Optionally, you can also have

the library indicate which parts need special attention because they are

polarized. This way, when you have a new design, you can simply import

the library, and it will automatically tag the part numbers on the

assembly.

Then, it’s easy to color them accordingly.

Here is an example of the

library: [Link to library

creation information.]

CRCW08051210F

Yellow=2 pin polarity imperative

CRCW080553323F

Yellow=2 pin polarity imperative

Alternatively, if you already

have this type of information—or any information—associated with the

part number in your MRP or ERP system, you can simply export it and

import it into Unisoft

for your PCB through the library.

Below are a few additional options for making polarized

components stand out for inspection or assembly; some of these have been

outlined above. We are

assuming you are an experienced user of the Unisoft

software. Please contact us for training.

OPTION: In the SMART COLOR window, you can assign a step number to the polarized components and print out a single sheet for that step number, which will contain only the polarized components in color.

OPTION: You can also create

a process step number—similar to the option above—for only polarized parts,

and print out a graphic section of only the PCB assembly (PCBA). Then, place

it as an annotation overlay graphic on top of the assembly

and bring it

to the forefront. The result is that only the polarized parts will be

visible on the display.

OPTION: Apply solid colors to only the polarized components on the display using the SMART COLOR window by using the COLOR 1 P/N feature. If you want them to all be the same color or a unique color, also use the CHANGE COLOR feature.

OPTION: If you have a PCB

assembly (PCBA) that consists mostly of polarized components and only a few

non-polarized components—for example, R1, R2, and U1—it may be quickest to

change the color of the pins and, if desired, the component bodies of these

non-polarized components to the same color as the background. At that point,

the non-polarized components will fade into the background and become

essentially invisible, while the colored polarized components will stand out

on the display. You can then use the display or a printout of the display

for inspection, assembly, etc.

More information:

For questions and training, please contact Unisoft.