Skip navigation

For over 35 years, Intelligent PCB Manufacturing

Automation Software

Be production ready in minutes, not days.

Related information:

Quoting by span: Assembly Cost/ or Time by Component Count Span Report for

Quoting

Quoting by p/n:

Assembly or Parts Cost or Time by Part Number Report for Quoting

Quoting/quality from solder joints: Solder Joint Count Report. Defect Per

Million Operations (DPMO)

Quoting from gerbers: Quoting Using Only Gerber

Files

Cycle Time is the time it takes to assemble a PC Board and in this case we are

dealing with the time it takes to insert the components on the PCB.

For example if you have a certain amount of Surface

Mount Devices (SMD) and Thru Hole Devices (THD) on your PCB assembly ( PCBA ) and there being

inserted at various machines and operations then how long will it take to do the

component placements either automatically or manually.

There are two methods for calculating Cycle Times with the Unisoft software, Cycle Times by component span and Cycle Times by part number.

For calculating assembly costs click here.

Cycle Times by component span - method #1

This method calculates the cycle time by component span and is usually the

preferred and easier method.

This method uses a component span template which can

be used to represent time or costs and if you wish to calculate Cycle Times then the numbers used

in the template represent time. These templates are located under “Assembly Cost

or Cycle Times by

Component Span” under the “Quote/Quality” menu.

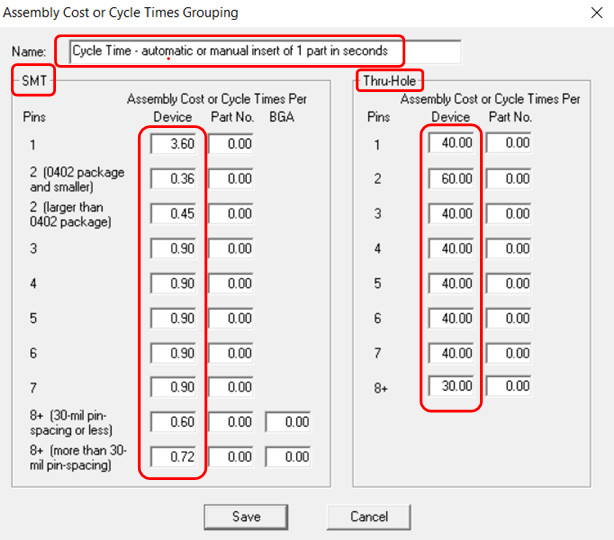

In the figure that follows we created a template

titled Cycle Time - automatic or manual insert of 1 part in

seconds . So in this template we used the time required for insertion placement for 1 component

in

seconds (note "seconds" are preferred). So essentially this would be the time to place 1 component

package in a

particular category in the time unit of seconds.

For example for SMD components in the

template table above we have listed for the component category SMT 2 (larger than

0402 package) the number 0.45 which stands for 0.45 seconds

for 1 placement of that package type. So 0.45 seconds for 1 component

insertion would equate to that machine placing 8,000 components in 1 hour in

that category - 1 hour=3600 seconds (3600/0.45=8,000).

As an example for THD components in the

template table above we have listed for the component category THD Pin=2 the

number 60.00 which stands for 60 seconds for 1

placement of that package type. So 60 seconds for 1 component insertion

would equate to hand placing 60 components in 1 hour in that category.

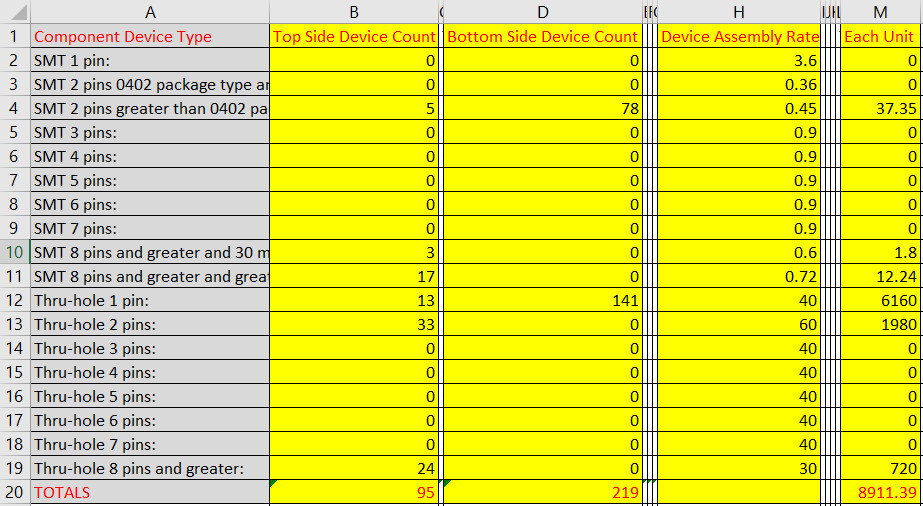

From the template window in the Unisoft software in

the figure below we generated the tab delimited Excel output report for the

template we created above. It breaks down the times per category for both

SMD and THD device types.

So in the figure above for the component category

SMT 2 pins greater than 0402 package: we see that there are 5 components on

the top side and 78 on the bottom with the rate of 0.45 seconds for 1

package placement and the total time required is 37.35 seconds.

In the figure above for the component category Thru-hole 2 pins: we see that there are 33 components on the top side and 0 on the bottom with the rate of 60 seconds for hand placement of 1 package and the total time required is 1980 seconds.

Cycle Times by part number - method #2

The second method for calculating cycle times is

Cycle Times by part number. Note Method # 1 Cycle Times by component span

is usually the preferred method.

--------------------

You can quickly create a Cycle Time by part number report. This report is used

by Contract and OEM manufacturers to quickly estimate Cycle Times. The report

contains the totals for the PC Board and breakdown by part number.

Total = 1973.66 seconds

----

381200-40-1 1 0.90 0.90

381212-44-1 4 60.00 240.00

385848-05-6 32 3.60 115.20

386754-99-4 1 40.00 40.00

389148-06-7 1 3.60 3.60

390579-03-3 1 90.00 90.00

390607-01-0 1 80.00 80.00

391727-10-9 16 0.45 7.20

391727-12-5 16 0.36 5.76

391727-13-3 1 0.90 0.90

391727-14-1 5 0.90 4.50

391729-02-0 16 0.90 14.40

391770-01-2 1 40.00 40.00

391770-02-0 1 0.90 0.90

391777-06-8 11 0.90 9.90

391777-08-4 16 0.90 14.40

391781-01-4 2 3.60 7.20

391809-01-6 1 40.00 40.00

391818-06-6 3 3.60 10.80

391822-01-2 1 3.60 3.60

391822-02-0 1 3.60 3.60

391822-03-9 1 3.60 3.60

391829-03-3 1 90.00 90.00

395382-01-7 1 90.00 90.00

395383-01-3 1 90.00 90.00

395422-01-9 8 0.90 7.20

396051-01-4 16 60.00 960.00

Creating

the Cycle Times by part number report:

The Cycle Time by Part Number Report uses the

part numbers to group together components times to determine the total cycle time.

To use the Cycle Time by Part Number method

you need to create a simple text file Library (.OPR) file with a minimum of two

elements per line: 1) The part number. 2) The

placement time for 1 component and it is recommended that it be in seconds.

You

can have as many Library (.OPR) files as you desire. For example you can have

one large Library (.OPR) file with as many Part Numbers in it as you wish or if

you're a contract manufacturer one for each customer you may have.

391727-10-9 Placement time for 1 component in seconds 0.45

391727-12-5 Placement time for 1 component in seconds 0.36

381200-40-1 Placement time for 1 component in seconds 0.90

391727-13-3 Placement time for 1 component in seconds 0.90

In the .OPR file above the part number is in

the first field followed by a TAB then the second field is the text instruction

field (Example: Placement time for 1 component in seconds) and this field is

optional and can be left blank. Next is another TAB and then the third field is

the rate field and this field can represent either time or money and in our case

here for cycle time it will represent time in seconds.

So in the

example .OPR above for the part number

391727-10-9 we see that

the rate is 0.45 seconds for 1 component package placement.

After you have created the .OPR file with the

part numbers and rate, open the desired PC Board with the BOM imported using the

Unisoft software. Next click FILE then then IMPORT LIBRARY (.OPR) and a new

window will appear. In the window point to and select the .OPR file you have

created and then click OPEN. Next to generate the Report click QUOTE/QUALITY

from the Main then click PARTS OR ASSEMBLY COST OR CYCLE TIMES BY PART NUMBER and the report

appears.

Note that to get the Assembly or Parts Cost by

Part Number Report it is not required to have the actual CAD or Gerber files

imported into the Unisoft software, you can import only the BOM and then import

the Library (.OPR) file and then create your report from the Unisoft software.

However be aware when using this method of only importing the BOM file you will

usually not receive the cross-checking necessary to determine the "Do Not

Install's" or any other item that may be wrong in the BOM before you generate

the report.

Also see - Assembly Cost by Component Span Report for Quoting templates

menu.

https://www.unisoft-cim.com/view-markup_download.htm#ASSIGNING_OPERATIONS_TEXT_TO_EACH_PART_NUMBER

https://www.unisoft-cim.com/features.htm#Launch_Browser_hyperlinks