Skip navigation

For over 40 years, Intelligent PCB Manufacturing

Automation Software

Be production ready in minutes, not days.

Below is the Unisoft Free Distance Calculator for

components on the PCB. Using this calculator, you can identify component

pins on unique reference designators where the pins on the components are

equal to or less than the distance you specify, for example, 75 mils (0.075

inches).

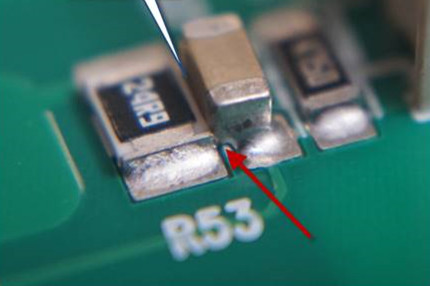

This calculator can be used, for instance, to detect

components that may be too close together, potentially causing quality

issues.

It is also useful for identifying SMT components that might

impact the design and effectiveness of a wave solder pallet. Typically,

there may be space to reposition the SMT components away from the thru-hole

solder joint, but during the PCB design phase, designers may be unaware that

such adjustments are necessary. Wave solder pallets are a special type

of fixture used during the wave soldering process to mask selected areas of

the printed circuit boards that require thermal or solder protection, for

example thru-hole devices. The

masked areas usually contain SMT components, ground planes, gold fingers

and/or mounting holes.

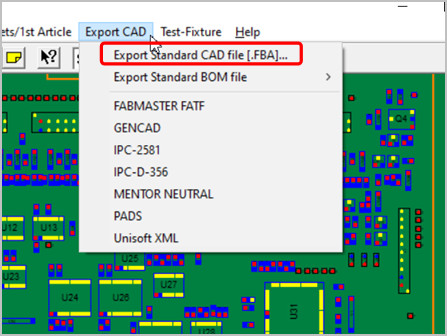

Export a .FBA File:

.FBA file. To

export the .FBA file, click EXPORT CAD, then click EXPORT STANDARD

CAD FILE [.FBA], and save the file to the directory of your choice.

The Calculator:

.FBA file to

compare each pin against all others on the PCB.

Running The Calculator: In the first box below,

click the 'BROWSE / CHOOSE FILE' button. Browse to the

.FBA file you wish to import, select the file, and then click

'OPEN'.

Enter the distance in the second box you

wish to check, in inches. Note: If a large number is entered, the resulting

list can become very large. It is recommended to use a reasonably smaller

number, typically under 0.20 inches.

Process the File by clicking

the 'PROCESS FILE' button. Any relevant data will be displayed below.

The tool calculates the distance between closely spaced pins up to

the specified limit. For example, it identifies all pins on unique reference

designators that are 150 mils (0.150 inches) apart or less, as shown in the

sample format below:

Ref. Des. #1 Pin

X Y

Surface Ref.

Des. #2 Pin X

Y Surface

Distance Between Pins

U4

11 -5.475 2.240

T

U6

48 -5.388 2.240

T

0.0870

R41

1 -5.250

1.395 T

U9

35 -5.350 1.400

T

0.1001

C1

1 -4.800

0.320 T

U1

14 4.700

0.360 T

0.1077

If you wish to save the data, the default file name is

'outputData.txt', displayed in the box below. You may change the file name

if desired. Once ready, click the 'SAVE DATA TO FILE' button to save the

data.

The above calculator is provided for informational purposes only.

Unisoft assumes no responsibility for any issues that may arise from its

usage.

Design for Manufacturing/Assembly/Test (DFM/DFA/DFT) for PCB

Manufacturing

Design for Manufacturing, Assembly, and Test

(DFM/DFA/DFT) for PCB manufacturing is a broad and complex subject area.

This comprehensive approach is aimed at designing printed circuit boards

(PCBs) in a manner that facilitates easier and more cost-effective

manufacturing.

DFM/DFA/DFT checks focus on optimizing the PCB design to align with manufacturing capabilities while minimizing potential issues that could arise during production. The primary goals are to enhance production efficiency, reduce costs, and ensure the quality of the final product.

Most aspects of DFM/DFA/DFT are addressed during the PCB design phase, utilizing sophisticated software and techniques provided by various CAD systems. These systems are essential for PCB design, with hundreds of DFM/DFA/DFT criteria to be verified. When applied correctly, adequate DFM/DFA/DFT measures ensure that potential manufacturing, assembly, and testing issues are mitigated before production begins.

Unisoft software, which imports various CAD files and Bills of Materials (BOM) from PCB CAD design systems, assists in verifying that DFM/DFA/DFT principles have been effectively applied to certain aspects of PCB design. For more detailed information on these methods, contact Unisoft directly or refer to the online help tooltips provided.

Areas where

the Unisoft software may assist in verifying that DFM / DFA / DFT was executed properly:

Component Placement

Spacing: The Unisoft software cross-checks that proper spacing between

components is maintained on the PCB by measuring the distance between pins

for unique

reference designators. This spacing is

typically addressed during the design phase of the PCB. Proper component

spacing enables efficient assembly and minimizes issues during soldering

processes.

Test Probe Access

Nets: The Unisoft software verifies that proper test probe access is

available by analyzing each electrical net trace to ensure accessibility for

test probes. This is also typically

addressed during

the PCB design phase. Ensuring adequate test probe access minimizes issues

during the testing phase of manufacturing, including functionality and

quality assurance. This

is a critical Design for Test

(DFT) consideration that facilitates In-Circuit Testing (ICT), Flying Probe

Testing, Functional Testing, and more.

PCB Test Probe Force

Analysis Visualization: Analyzes stresses on the PCB induced by

test probes that press into the PCB, with consideration for offset vectoring

via the placement of push fingers.

Assembly and

Fabrication Notes: Includes detailed notes and specifications for the

manufacturer regarding assembly processes, material requirements, and any

special handling or processing

needs. The Unisoft

software creates process assembly documents to facilitate this.

Supply Chain Considerations:

Design for Manufacturing (DFM), Design for Assembly (DFA), and Design for

Testability (DFT) can extend to include considerations of the supply chain,

such as the

availability of components, lead times,

and the impact of using alternate parts. Early consideration of these

factors helps avoid delays and redesigns caused by unavailable parts or

longer-than-expected

lead times. The Unisoft

software's lookup feature by manufacturer part number, among other

capabilities, can significantly aid in this area.

Webpage proofed using AI in 2024